How Flexible Screw Conveying Works

Manufacturing Matters University

• 32 min

Play episode

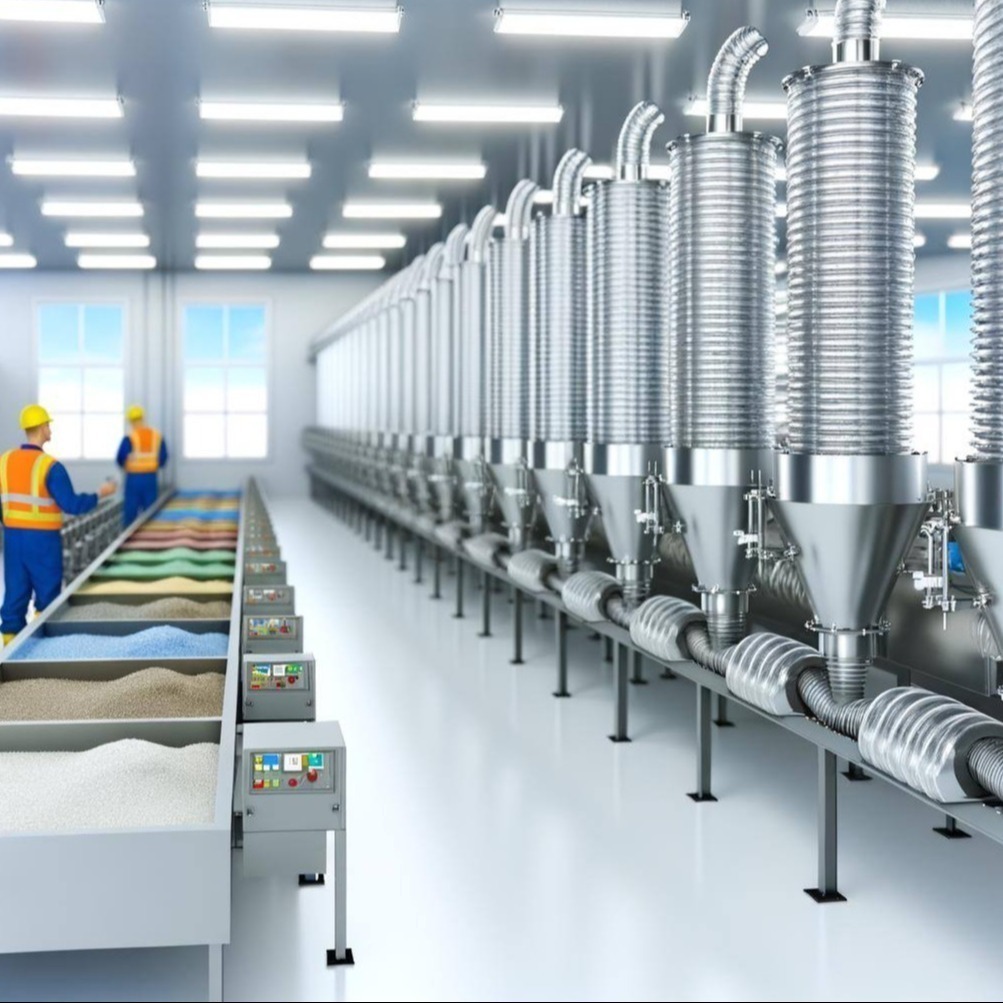

In the latest episode of "Manufacturing Matters," titled "How Flexible Screw Conveying Works," I delve into the intricacies of flexible screw conveyors, exploring their design, functionality, and benefits. We start with an introduction to the basic components and design, highlighting the simplicity and efficiency of these systems. The operational mechanism is then explained, detailing how the screw rotates within a tube to move materials from one point to another.

Key features and advantages are discussed next, emphasizing the flexibility, cost-effectiveness, and ease of installation that make these conveyors a popular choice in various industries. I also touch on the reliability and maintenance aspects, noting that these systems require minimal upkeep and are built to last.

The episode further explores the versatility of flexible screw conveyors, showcasing their ability to handle a wide range of materials, from powders to granules. Cleanliness and hygiene are also covered, with a focus on how these conveyors can be designed to meet stringent sanitary standards.

Optional features and enhancements are discussed, providing insights into how these systems can be customized to meet specific needs. Finally, I wrap up with real-world applications and use cases, illustrating the practical benefits of flexible screw conveyors in different manufacturing environments.

Loading