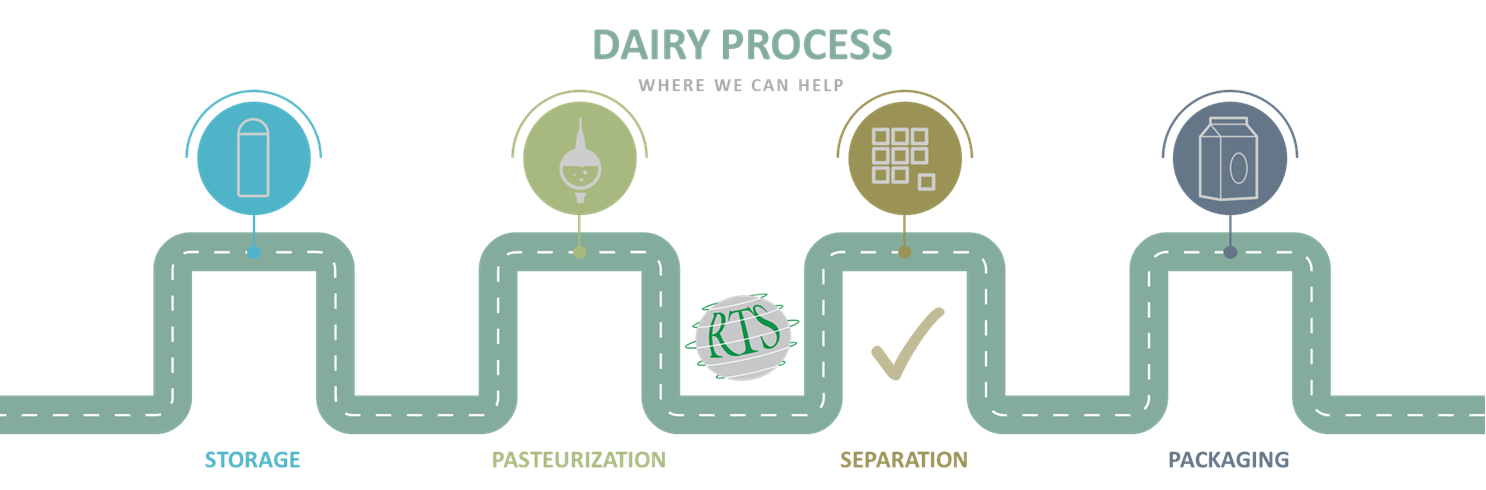

DAIRY PROCESS

Pneumatic Conveying

Dairy Plants depend on pneumatic conveying technologies

Pneumatic conveying has fewer moving parts and greater flexibility for plants with changing needs. Enclosed pipelines protect the material from contamination and virtually eliminate degradation of the product into smaller particles that can present a dust hazard. Pneumatic conveying also integrates filtration while delivering materials to their destination.

Dilute phase pneumatic conveying systems operate on the principle that the solids will be suspended in the conveying line air stream. This is accomplished by metering product into a moving air stream.

With no mechanically moving parts, pneumatic conveying is often used in many dry material applications. This type of system is comprised of a blower, filter, receiver, piping and discharge points. Pneumatic conveying can achieve conveying to distances and configurations that other conveying equipment cannot.

Pneumatic Conveying System

Dilute Phase Pneumatic Conveying is ideal for transporting a wide range of dry bulk materials in a simple and cost effective manner. Materials are fed into a high velocity gas stream by use of rotary airlock valves and carried through pipelines to the destination.

The use of vacuum and pressure conveying options facilitates the handling of materials from multiple source points and can distribute to multiple destinations. Dilute phase conveying also supports flexible pipe routings (horizontal, vertical and turns) ideal for new and retrofit installations. The standard piping and associated filters result in an enclosed transport environment making for a safe, sanitary and clean mode of transport.

Products commonly conveyed in dilute phase systems include flours, resins and compounds, specialty chemicals, ground feeds, and granular and pelletized products.

Common types of dilute phase systems supplied by Schenck Process include: pressure, vacuum, combination vacuum/pressure and vacuum sequencing.

Pressure Dilute Phase

- Easy to go from a single source to multiple destinations

- Increased process efficiency

- Requires some available head height at source but can convey directly into silos/bins

Vacuum Dilute Phase

- Pull from multiple sources to a single destination

- Feed airlock helps control line loading

- Easy to create a dust free environment

Vacuum/Pressure dilute phase combination

- Combines advantages of both pressure and vacuum systems

- Utilizes some equipment such as the rotary airlock in dual service

Vacuum Sequencing

- Vacuum receiver is filled with material on time or level intervals

- Simple operation can be based on time or level in a hopper, feeder or other bulk material handling equipment.