Welcome to our selection of

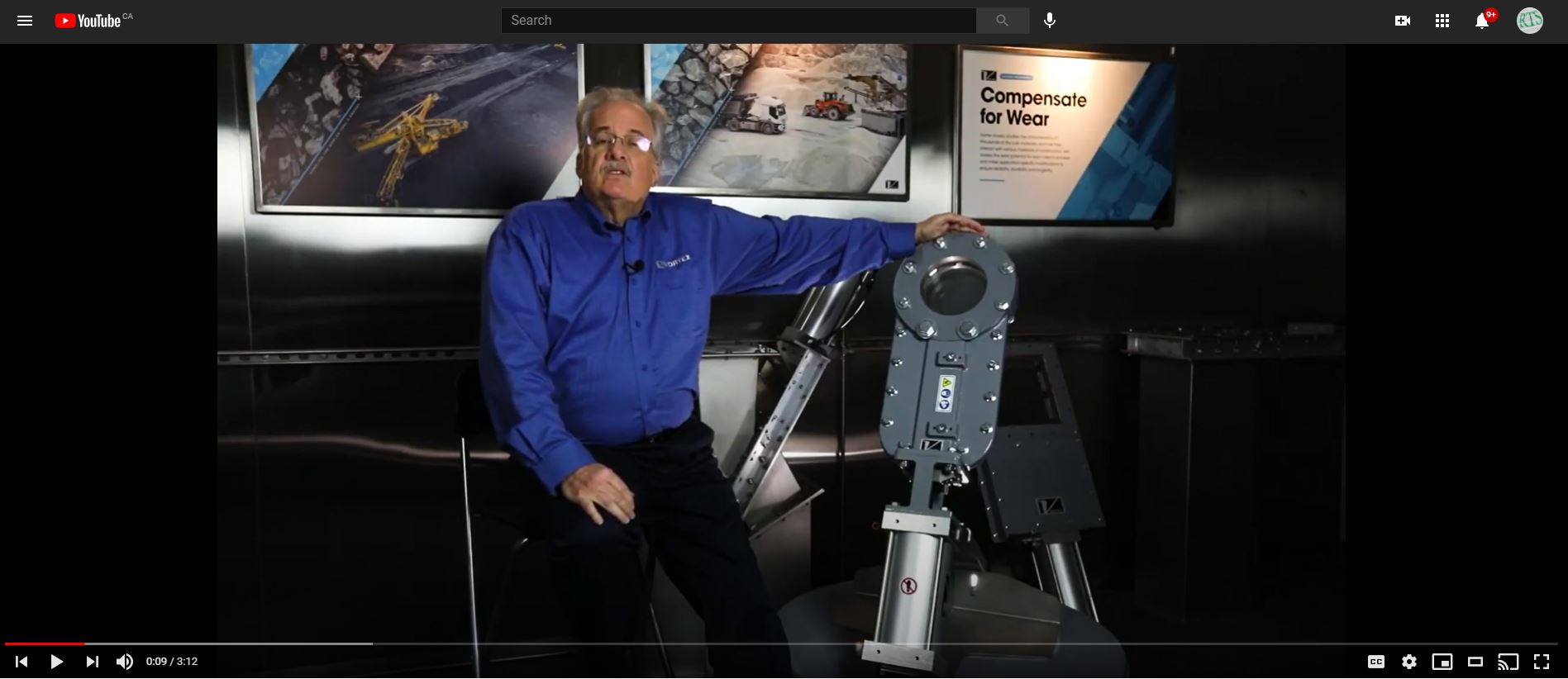

Vortex Valve videos

Vortex specializes in the design and manufacture of components for the transport and flow control of dry bulk solids. Vortex’s technical focus is in the development of innovative technologies to improve solids process efficiency, ensure dust-free environments, and establish long-term reliability.

Vortex Gate Valves, Diverters & Loading Solutions

After viewing the videos below you will likely note our depth of application experience. We have something for each application.

The VORTEX Titan Valve Series Catalog

Staying true to the Vortex design philosophy, we identified a need in theheavy-duty and abrasive material handling industries. When handling suchmaterials, the most common causes of equipment maintenance orreplacement are erosive wear and impact wear, which causedamage to a valve’s internal parts. The Vortex Titan Series isspecifically designed to protect against these forms of wearand abrasion. Characterized by unique design androbust metal materials of construction, the VortexTitan Series features slide gates and divertersbuilt for durability, reliability, ease ofmaintenance and prolonged service life.