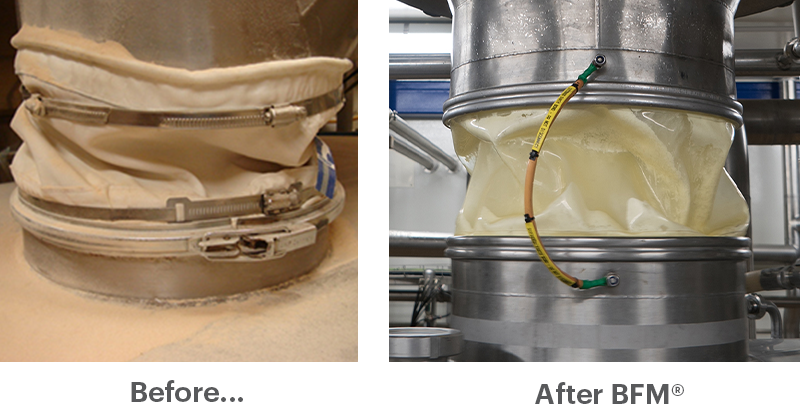

Convey, load, unload, weigh, feed, and process virtually any bulk solid material

For over a decade now, we’ve been proud to exclusively represent Flexicon in the Canadian manufacturing sector. You and your team will love that Flexicon focuses on supporting manufacturers like you with the conveying (flexible screw, pneumatic/vaccuum, tubular cable), loading (bulk bag or super sac), unloading (bulk bags, 25kg bags, containers, boxes and drums), weighing, feeding, and processing of bulk materials across their facilities—while maintaining a strong balance between productivity and safety. With more than 50 years of experience designing and implementing bulk material handling systems, Flexicon is backed by a multidisciplinary team of specialists whose combined expertise spans hundreds of years.

Having executed multiple projects in Canada, you can rest assure that everything supplied to Canadian Customers can be offered with 575 volt motors and drives, CSA Certifications, 3A Dairy Certifications, Explosion Protection Considerations and much more! Request a quote to learn more!