BULK BAG DISCHARGER SYSTEMS

QUOTE REQUEST | Product Video | Quick Ship (approx 3 weeks) | Spare Parts Inquiry

At Rate Technology Systems, we are the exclusive Canadian representatives of Flexicon®, a global leader in dry bulk material handling solutions.

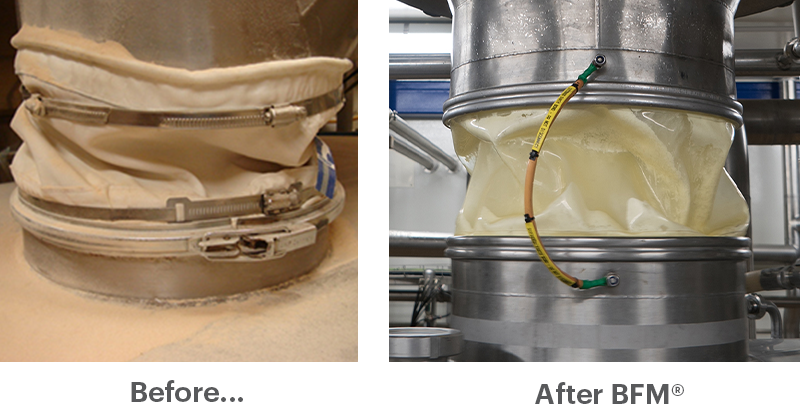

Flexicon’s bulk bag dischargers are engineered for clean, dust-free unloading of materials, allowing for easy loading, untying, retying, and removal of bulk bags.

These systems come in multiple configurations—some equipped with lifting frames for forklift handling, and others featuring cantilevered I-beams with electric hoists and trolleys to eliminate the need for forklifts altogether.

Built with industrial-grade carbon steel or corrosion-resistant stainless steel, these dischargers are suitable for demanding environments—including food, dairy, and pharmaceutical operations.

Send us a Quote Request, and let us help you engineer the right solution for your plant.

Yes, we are able to offer 575v and CSA certs on motors and electrical components!

|

|

Available Models

|

BULK-OUT® BFC Hoist Unloader

Equipped with a cantilevered I-beam, electric hoist, and trolley system, this model eliminates the need for a forklift, offering increased flexibility in material handling and improved operator efficiency.

|

|

BULK-OUT® BFF Forklift Unloader

Includes a detachable bag-lifting frame that allows operators to attach bag loops at floor level, enabling quick and convenient loading and unloading using a forklift.

|

|

BULK-OUT® BFH Half-Frame Unloader

Designed as a cost-effective solution for operations with existing lifting infrastructure, this model requires a forklift or overhead hoist to suspend the bag during discharge.

|

How Does this System work?

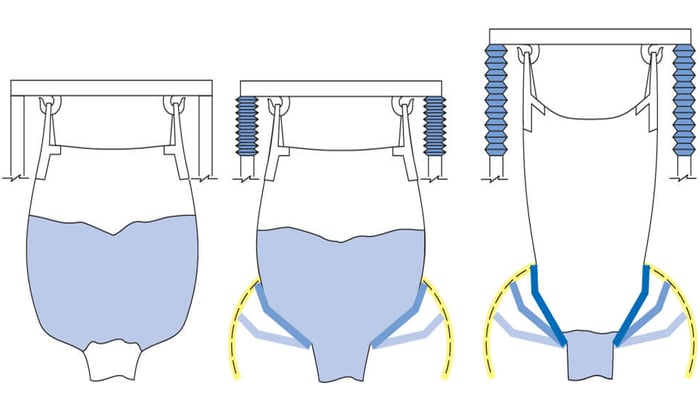

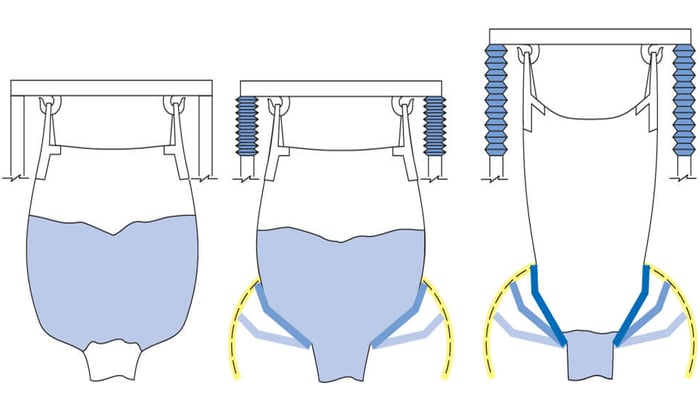

FLOW-FLEXER® Bag Activators: These pneumatically powered devices gently press the bottom of the bag at regular intervals, helping direct contents downward toward the outlet and enhancing material flow. FLOW-FLEXER® Bag Activators: These pneumatically powered devices gently press the bottom of the bag at regular intervals, helping direct contents downward toward the outlet and enhancing material flow. |

POP-TOP™ Bag Stretchers (for BFF models): As the bag empties, this mechanism lifts the bag’s corners to create a "V" shape, improving flow of sluggish or compacted materials.  |

|

SPOUT-LOCK® Clamp Ring

This system creates a tight, sealed connection between the bag spout and the discharger's receiving tube. It ensures no dust escapes during untying, discharging, bag collapse, or removal.

Quick-release levers provide tool-free connection, and in many cases, it eliminates the need for flow control valves—unless retying a partially discharged bag.

|

|

TELE-TUBE® Telescoping Tube

The telescoping design maintains constant downward pressure on the bag spout during discharge.

This prevents the spout from sagging inward (causing blockages) or ballooning outward (forming dead zones), which helps promote continuous flow and full evacuation of material.

|

|

POWER-CINCHER® Flow Control Valve

Unlike traditional pinch bars, this advanced valve uses curved stainless rods that cinch the spout evenly for a tight seal—vertically and concentrically.

It allows for controlled discharge and resealing of partially emptied bags without leaks, even with fine powders.

|

|

Iris Valve Option

When a sealed interface isn’t needed, a traditional iris valve can be used to temporarily close the spout during untying, then gradually opened for controlled discharge.

This is a cost-effective alternative for applications where dust containment isn’t critical.

|

| Construction Materials: - Flexicon bulk bag dischargers are engineered for durability and strength. The heavy-duty frame supports bags securely throughout discharge. Systems are available in: Carbon steel with industrial-grade coatings for robust, long-lasting performance or Stainless steel for sanitary or corrosive environments (food, pharma, or chemical processing) |

|

|

|

BENEFITS OF OUR BULK BAG DISCHARGER SYSTEMS – Why these are used instead of our Competitors

|

CLEANLINESS - Complete Dust Control - Flexicon’s bulk bag dischargers are engineered to maintain a dust-free environment during bag handling and material transfer. Key design features include:

- POWER-CINCHER® Flow Control Valve: This valve uses a series of curved stainless steel rods to evenly constrict the bag spout, ensuring a secure, dust-tight closure and allowing clean retying of partially discharged bags.

- TELE-TUBE® Telescoping Tube: Maintains continuous downward tension on the spout, preserving a tight seal to eliminate dust emissions throughout the discharge cycle.

- SPOUT-LOCK® Clamp Ring: Provides a robust, sealed connection between the bag spout and discharge tube, preventing contamination during connection and material flow.

- BAG-VAC® Dust Collector: Applies negative pressure to collapse empty bags and extract remaining particles from folds, enabling a clean and dust-free bag removal process.

- Sanitary Construction: Available in stainless steel with USDA-accepted and FDA-compliant components, the sanitary models feature easy-to-remove parts and quick-release clamps, ideal for food, dairy, and pharmaceutical operations.

|

|

ECONOMICAL ADVANTAGES - Lower Operating and Material Costs - Flexicon bulk bag dischargers help reduce total production costs through smarter material handling:

- Bulk Purchase Efficiency: Handling larger volume bags cuts material costs compared to multiple smaller bags.

- Labor Reduction: Automating the discharge process minimizes manual labor and boosts throughput.

- Material Waste Minimization: Efficient evacuation reduces leftover powder, decreasing loss compared to using multiple small bags.

- Reduced Packaging Waste: Fewer bags mean less packaging waste; some bulk bags are even reusable, further lowering packaging costs.

|

|

PERFORMANCE - Optimized Material Flow and Handling - Advanced engineering delivers reliable and consistent discharge performance:

- Integrated Flow Enhancers: FLOW-FLEXER® activators, POP-TOP™ extenders, and TELE-TUBE® tubes collaborate to promote smooth material flow and eliminate clogs.

- Leak-Free Retying: The POWER-CINCHER® valve enables fast, secure retying of partially emptied bags without mess.

- Simplified Bag Loading: Designed with operator efficiency in mind:

- Z-CLIP™ Strap Holders allow quick bag attachment.

- Integrated Hoist & Trolley (Model BFC) eliminates the need for forklifts.

- Wide Forklift Pockets (Model BFF) enable safe and easy bag positioning.

- TELE-TUBE® Access simplifies spout connection and tie-off.

|

Options & Configurations

|

Flexicon's BAG-VAC® dust collection system creates a sealed environment that enables clean and efficient emptying of bulk bags.

By generating negative pressure within the system, the BAG-VAC® gently collapses the empty bag before tie-off, eliminating the dust clouds that typically result from manually flattening bags.

This system also removes residual particles trapped in the folds of the spout during disconnection, eliminating the need for hard-to-reach access ports. Venting options include a filter sock, a centralized dust collection setup, or the standalone BAG-VAC® unit itself.

|

|

|

Mobile Configurations for Plant-Wide Flexibility - All Flexicon bulk bag dischargers can be mounted on caster-equipped frames with vertical support masts, allowing operators to easily move equipment throughout the facility for versatile, on-demand material transfer wherever it’s needed.

|

Multi Purpose Hopper Interface - This feature allows for automatic bulk bag discharging, as well as manual dumping of 25kg bags or 50 pound bags.

The operator can raise the hinged door and pour material through a coarse screen

|

|

Bag Piercer Hopper - This is designed to be used with spoutless, single trip bulk bags, and includes a static blade assembly that is located in a large hopper to pierce the the bag and allow material to discharge

|

Safety Cage - This feature is for applications that call for operators to be prevented from coming in contact with moving parts during operation of unloading bags. This is designed with an intrinsically safe relay that stops operation when the door is open

|

|

Bag Conditioner and Unloader Combo System - This is used to break up and loosen up material that has solidified during shipment and makes unloading the material much easier.

|

Skid Mounted Station - This configuration is designed to fill bulk storage areas that cannot be reached by rail or bulk truck

|

|

Mobile Half Frame - Can be used anywhere in the plant, and easily moved around. This system relies on an existing forklift or plant hoist

|

Split Frame Unloader - Used in low headroom areas, this split frame allows discharging or bulk bags or rigid totes. This design allows for the upper frame to be forklifted on the plant floor, loaded and then forklifted back onto the sub frame

|

|

Explosion Protection Considerations- We can offer CSA XP rated motors and electrical enclosures if required. Please let us know if you have an application that would have this requirement. Do you have your KST and Pmax values of your material ready? This is a key piece of information for this topic. |

|

|

Where Can These Bulk Bag Dischargers Be Used?

|

|

Efficient Gravity-Fed Discharge - Ensure smooth and reliable gravity feeding of materials from bulk bags to downstream processes or containers using Flexicon’s purpose-built dischargers. These systems support gravity transfer with customizable frame options and can be outfitted with access platforms to accommodate height requirements for specific processing lines. |

|

|

Solutions for Low-Clearance Installations - Flexicon’s low-headroom dischargers are ideal for facilities with restricted vertical space. Featuring compact or split-frame constructions, these systems enable safe, easy bag loading without needing forklift masts to rise above the frame—offering both convenience and space efficiency in tight environments.

|

|

|

Discharging Solidified or Compacted Bulk Bags - Handle hardened or tightly compacted materials with ease. Flexicon dischargers can be equipped with hydraulic bag conditioning rams, loosening solidified contents inside the bag for complete and uniform discharge—streamlining operations and eliminating the need for separate conditioning equipment.

|

|

|

Dual-Mode Operation: Bulk Bags & Manual Dumping - Enhance operational flexibility with Flexicon’s Multi-Purpose Hood, which allows both automated unloading from bulk bags and manual dumping from sacks, drums, or boxes. When paired with an optional dust collection system, this solution supports clean and adaptable material transfer for various container types.

|

|

|

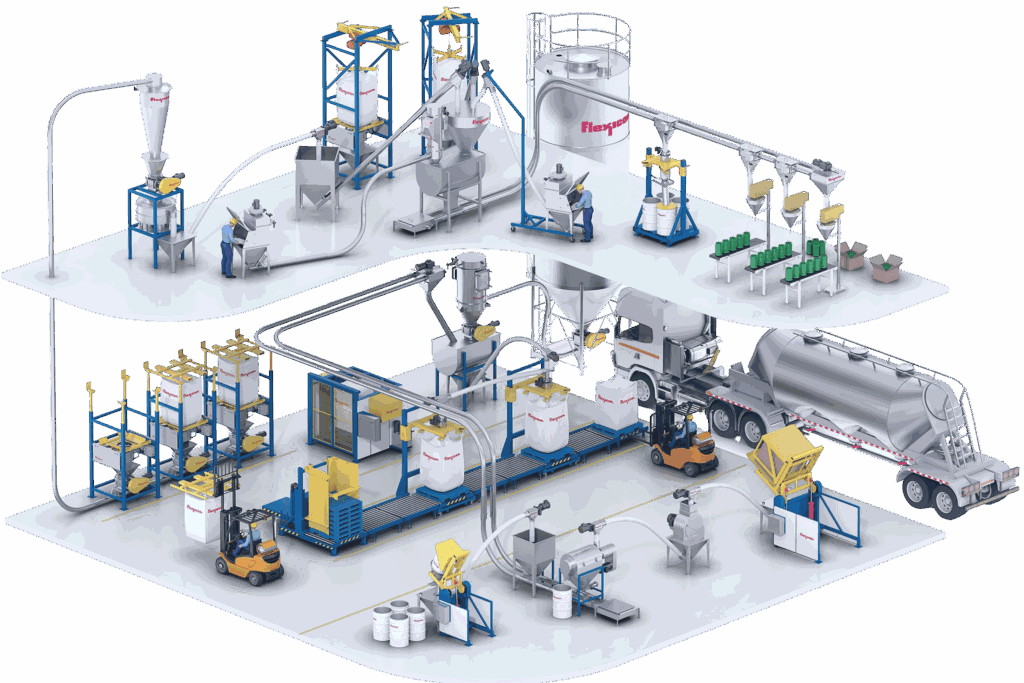

Seamless Integration with Conveying Systems -

Flexible Screw Conveyors: Dischargers provide controlled, dust-sealed feeds directly into flexible screw conveyors, enabling short to medium distance transfers.

Pneumatic Conveying Systems: Integrate with pneumatic systems to achieve high-speed, dust-free conveying of fine or powdered materials.

Tubular Cable Conveyors: Provide enclosed, contamination-free loading of friable or delicate materials into tubular cable systems for gentle, sealed transport.

|

|

|

Precision Feeding to Weigh Batching Systems - Flexicon bulk bag dischargers deliver steady and accurate feeding to weigh batch systems, supporting precise dosing and measurement of ingredients in batching operations, ideal for food, chemical, and pharmaceutical applications.

|

Featured Case Study: Tereos Artenay Sugar

Tereos Artenay Modernizes Sugar Handling with Pneumatic Conveying - At its Artenay, France facility—operational since 1953—Tereos processes 11,500 tonnes of sugar beets daily and produces consumer sugar products, alcohol, and animal feed. To support new 1 kg sugar carton and cube production, the plant installed a Flexicon pneumatic conveying system to handle bulk bags of extra-fine sugar from another Tereos site.

System Overview - Bulk bags are unloaded using a hoist-equipped discharger, feeding sugar into a Flexicon PNEUMATI-CON® system. A diverter directs the sugar either to cube production or a packaging line, via vertical and horizontal runs up to 30 m long.

Cube Line - Sugar is conveyed to hoppers where it’s mixed with water and molded into cubes.

Carton Packaging Line - The system also delivers sugar to a large hopper for continuous packaging into 1 kg cartons.

Why Pneumatic? Belt conveyors were impractical due to required vertical lifts. Pneumatic conveying offered a compact, sealed, and food-safe solution. Flexicon was chosen for its ability to meet the plant’s specific flow rate requirements.

Challenges Addressed - The mixed sugar and starch material risked separation during conveying. Tereos collaborated with its supplier and Flexicon to improve material homogeneity and ensure system performance.

|

|

FLOW-FLEXER® Bag Activators: These pneumatically powered devices gently press the bottom of the bag at regular intervals, helping direct contents downward toward the outlet and enhancing material flow.

FLOW-FLEXER® Bag Activators: These pneumatically powered devices gently press the bottom of the bag at regular intervals, helping direct contents downward toward the outlet and enhancing material flow.