BULK BAG CONDITIONER SYSTEMS

QUOTE REQUEST | Product Video | Quick Ship (approx 3 weeks) | Spare Parts Inquiry

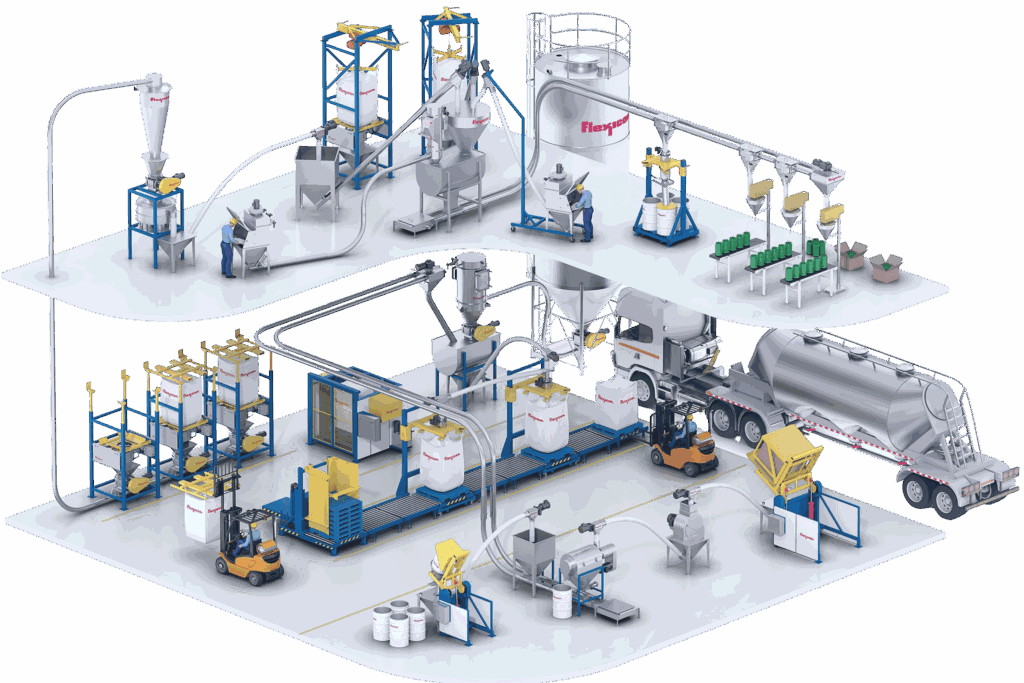

At Rate Technology Systems, we are the exclusive Canadian representatives of Flexicon®, a global leader in dry bulk material handling solutions.

The Flexicon Bulk Bag Conditioner is designed to break up compacted or moisture-affected materials—such as chemicals, food ingredients, hygroscopic powders, and other bulk solids—that may harden during storage or transport.

By restoring the material to a free‑flowing condition, the conditioner allows bulk bag unloaders to empty contents smoothly through the bag spout without interruption.

Flexicon offers this as a stand alone station, or combined with a Bulk Bag (Super Sac) Unloading System.

Send us a Quote Request, and let us help you engineer the right solution for your plant.

Yes, we are able to offer 575v and CSA certs on motors and electrical components!

|

|

How Does this System work?

|

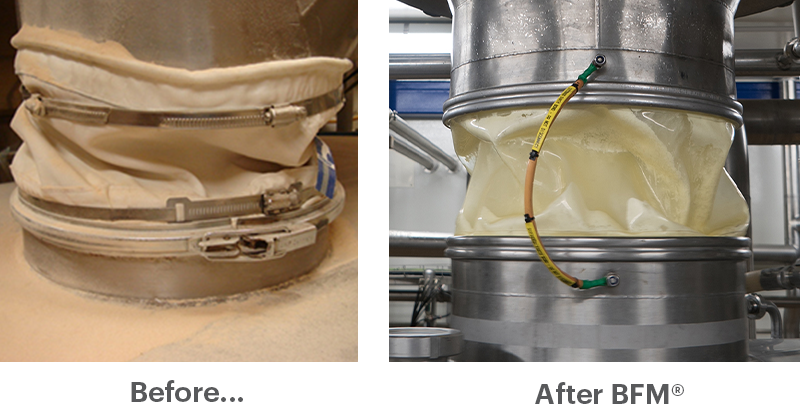

Flexicon's BLOCK-BUSTER® Hydraulic Bulk Bag Conditioners—also known as FIBC, Big Bag, or Jumbo Bag Massagers—are designed to break up solidified bulk materials that have hardened during storage or transport.

These materials may be too compacted for traditional pneumatic flow aids. Using two hydraulic rams, the system applies force to loosen the contents, allowing bulk bag dischargers to effectively empty them through their outlet spouts.

These conditioners can be integrated into discharging systems or configured as freestanding units in two different models.

Bag Compatibility:

Maximum weight capacity: 4,000 lb (1,800 kg)

Accommodates bags between 36 to 72 inches (965 to 1850 mm) in height

Fits seam widths up to 36 inches (915 mm) and filled widths up to 48 inches (1220 mm)

Pallet Accommodation: Handles pallet sizes up to 48 inches (1220 mm) square.

|

|

Dual Hydraulic Rams - Opposing hydraulic rams are equipped with specially shaped compression plates & apply adjustable force to the bag for effective conditioning.

|

Programmable Lift & Turntable - A scissor lift combined with a rotating platform allows comprehensive conditioning of all sides and heights of the bag.

|

Durable Frame - Built with heavy-duty carbon steel and coated for industrial performance.

|

Safety Enclosure - Comes with a four-sided safety cage and hinged doors, including a NEMA 4 interlock switch for operator protection.

|

Hydraulic Power Unit - Included for ram operation.

|

Control Panel - CSA-listed, housed in a NEMA 4 enclosure.

|

Construction Materials: - Flexicon offers these conditioners in carbon steel with tough industrial coatings or in stainless steel for sanitary or corrosion-resistant applications. |

|

|

|

BENEFITS OF OUR BULK BAG CONDITIONER SYSTEMS – Why these are used instead of our Competitors

|

Safety

Automated Bulk Bag Conditioning - Eliminate the risks associated with manual methods like using forklifts, pipes, or makeshift tools to break up hardened materials in bulk bags. Flexicon’s system automates the process, improving safety and reducing operator fatigue.

Comprehensive Safety Features - Every Flexicon BULK-OUT® conditioner is enclosed with a fixed three-sided safety cage. Operator access is regulated via either full-length safety doors or an integrated light curtain system—ensuring compliance and safety in high-traffic production environments.

|

|

Operational Efficiency

Integrated System Design - By combining the bulk bag conditioning and unloading functions into a single piece of equipment, facilities reduce capital expenditure and free up valuable floor space otherwise needed for multiple machines.

Lower Labor Requirements - Hydraulic components and programmable controls drastically reduce the need for hands-on operation, leading to labor cost savings and more efficient use of workforce resources.

Continuous, Predictable Material Flow - Proper conditioning ensures that even hardened materials discharge smoothly, enabling a steady, clog-free flow that supports uninterrupted downstream processing.

|

|

Optimized Performance

Powerful Hydraulic Conditioning - The system utilizes robust hydraulic rams paired with contoured compression plates to break apart compacted materials safely and thoroughly, restoring them to a free-flowing state.

Turntable with Adjustable Height - A variable-height rotating platform enables conditioning from multiple angles and elevations, maximizing the effectiveness of each cycle and accommodating a range of bag sizes.

Hands-Off Automation - Operators simply place the bulk bag into position—after that, the automated system executes a complete conditioning sequence without further manual involvement. This ensures uniform, repeatable performance while reducing operational variability.

|

Options & Configurations

|

Hoist & Trolley

This model suspends the bag with a hoist and trolley system and then uses two hydraulic rams with contoured plates to press opposite sides of bulk bags, loosening hardened material for easy discharge through the spout.

|

Combo with Unloader Station

This integrated model breaks up solidified material inside bulk bags so it can discharge cleanly through the spout. By combining conditioning and unloading in one system, it eliminates separate handling steps, reduces labor and floor space, and lowers overall equipment and installation costs.

|

|

Laser Safety Curtain

This model uses a laser safety curtain that instantly halts the hydraulic rams, lift, and turntable if the beam is broken, providing operator protection without the need for safety doors or interlocks.

|

Inline System

This skid‑mounted system includes two bulk bag unloaders with integrated hydraulic conditioners that use dual contoured rams to loosen compacted material. Cantilevered hoists and powered trolleys allow bags to be loaded, positioned, and conditioned at multiple heights without forklifts, while safety interlocks prevent operation when access doors are open.

|

|

Explosion Protection Considerations- We can offer CSA XP rated motors and electrical enclosures if required. Please let us know if you have an application that would have this requirement. Do you have your KST and Pmax values of your material ready? This is a key piece of information for this topic. |

|

Featured Case Study: Morgan Advanced Materials

Morgan Advanced Materials Speeds Up Pitch Handling with Bulk Bag Conditioner

At its Morriston, UK facility, Morgan Advanced Materials replaced its labor-intensive and hazardous method of breaking solidified pitch—previously done with a backhoe—with a Flexicon BLOCK-BUSTER® Bulk Bag Conditioner. This upgrade has made the process 10 times faster and significantly safer.

Challenge: Solidified Pitch in Bulk Bags

Viscoelastic pitch, used in carbon product manufacturing, often arrives solidified due to long-distance shipping and temperature shifts. Once solid, it becomes tough to discharge and process.

Solution: Automated Conditioning

The hydraulic Bulk Bag Conditioner softens pitch by compressing the bag from multiple angles while rotating it automatically. This breaks the material into manageable lumps that are then easily discharged and further processed.

Impact

The system dramatically cut conditioning time and improved safety. It runs daily and integrates directly with Morgan’s production line. According to Production Manager Jeff Lloyd, it provides efficient, controlled, and safe pitch handling to support their output of over 7,000 high-performance products.

|

|