BULK BAG FILLER SYSTEMS

QUOTE REQUEST | Product Video | Quick Ship (approx 3 weeks) | Spare Parts Inquiry

At Rate Technology Systems, we are the exclusive Canadian representatives of Flexicon®, a global leader in dry bulk material handling solutions.

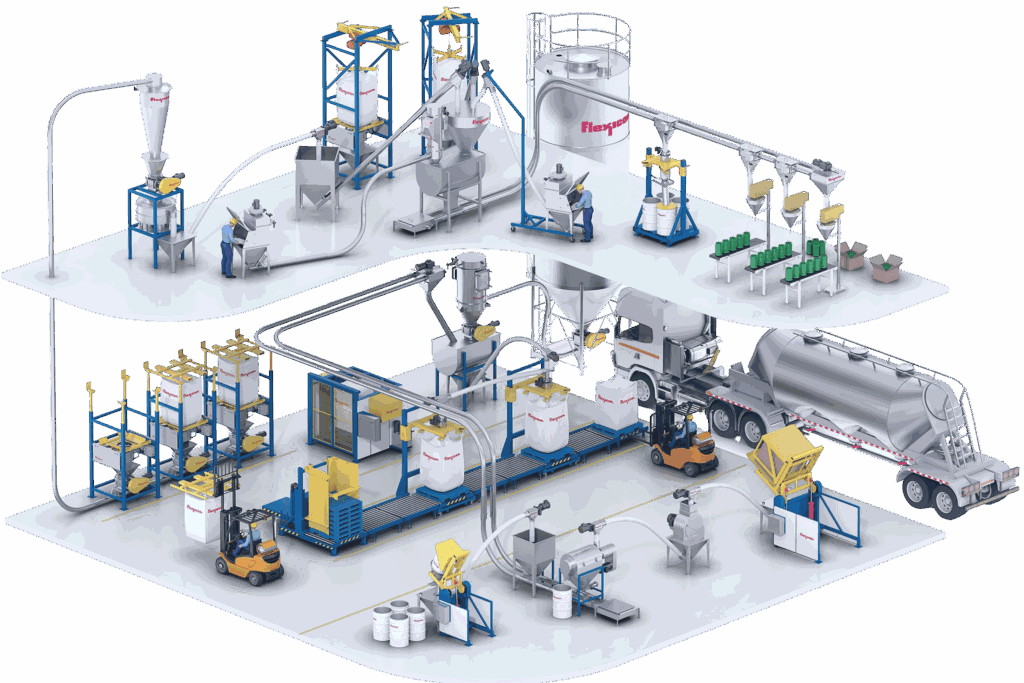

Flexicon provides a comprehensive range of bulk bag filling systems—from basic stand-alone units to fully integrated, automated lines.

These systems may include roller conveyors, pallet dispensers, and advanced automation controls, all tailored to meet your specific production volume, space, and budget requirements.

Each configuration is optimized for its intended throughput to deliver maximum operational efficiency and cost-effectiveness.

Send us a Quote Request, and let us help you engineer the right solution for your plant.

Yes, we are able to offer 575v and CSA certs on motors and electrical components!

|

|

Available Models

|

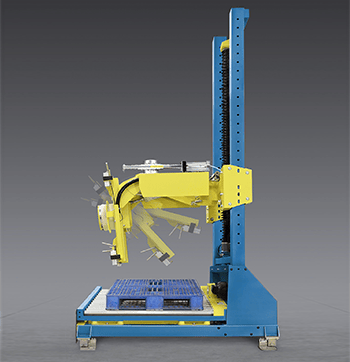

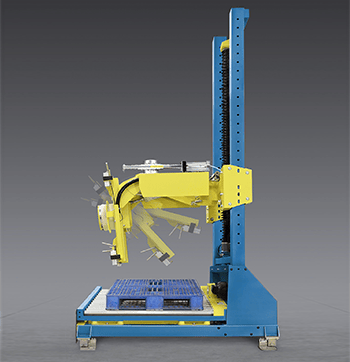

SWING-DOWN® Bulk Bag Filler

Designed for medium to high-volume operations, this high-performance unit features a fill head that lowers to floor level, allowing operators to attach bags easily, quickly, and safely.

This ergonomic design is ideal for integration with systems that include pallet handling and roller conveyors.

|

|

REAR-POST Bulk Bag Filler

A robust, versatile option also suited for medium to high-capacity needs.

This model handles most bag filling applications and supports integration with automation systems such as pallet dispensers and conveyors.

|

|

BASIC Bulk Bag Filler

A practical and economical solution for facilities that don’t require automated features.

It retains essential capabilities of higher-end units while offering a more lightweight frame, making it a great entry-level option.

|

How Does this System work?

|

Pneumatically Retractable Bag Hooks - Air-powered retractable hooks partially lift the bulk bag during the filling process. This ensures optimal bag shaping, enhances stability, and maximizes the use of internal space. At the end of the filling cycle, the loops are released either manually or automatically.

Air Displacement Outlet - An integrated air outlet—hidden within the discharge spout assembly—allows connection to a sock filter, cartridge filter, or dust collection system to control displaced air during filling.

Bulk Bag Filler Inlet - Material can be fed into the filler via a range of Flexicon systems, including Flexible Screw Conveyors, Tubular Cable Conveyors, Pneumatic Conveying Systems, or directly from overhead storage bins. A variable flow control valve regulates material input for precise filling.

Discharge Spout - The discharge spout is composed of concentric tubes that create an annular space. This design allows air to flow inward during bag inflation and outward while the bag fills, maintaining consistent shape and pressure.

Inflatable Collar - A flexible, inflatable collar securely grips and seals the bag’s inlet spout. Once filling is complete and the bag hooks are disengaged, the collar automatically deflates to release the bag.

Fill Head Height Adjustment - The filling head’s height can be adjusted using forklift-compatible fork tubes to accommodate various bag sizes. A powered adjustment option is available for automated or higher-volume operations.

Load Cells with Overload Protection - Built-in load cells monitor weight increase during the filling process. This data is transmitted to the control system, which regulates material flow by starting or stopping conveyors or operating flow control valves. The system also includes overload protection for safe operation.

|

|

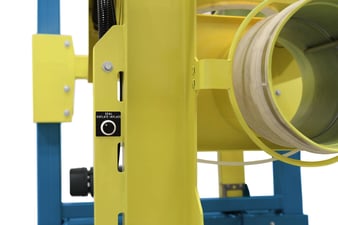

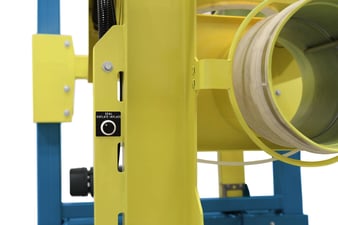

OPTIONAL - Bag Inflation Blower

This feature inflates the bag before filling to remove wrinkles and pre-form the shape.

It ensures that material fills all corners of the bag, providing excellent stability for stacking or transport.

|

|

OPTIONAL - Powered Fill Head Adjustment

An upgraded version of the manual height adjustment allows powered control to fit a wide range of bag dimensions with minimal effort.

|

|

OPTIONAL - Vibratory Deaeration/Densification Deck

Available with electric or pneumatic operation, this high-amplitude, low-frequency vibration platform densifies material inside the bag.

Inflatable air mounts isolate the weighing mechanism from vibration to maintain fill accuracy.

|

|

Conveying Systems for Bag Handling

Flexicon offers multiple roller conveyor solutions that enhance automation, reduce manual labor, and ensure smooth handling of filled and empty bulk bags throughout the filling process:

- Filling Station Roller Conveyor

A powered conveyor integrated with the bag filler to automatically move filled bags to downstream conveyors.

- It can also position empty pallets beneath the filler when paired with a pallet dispenser.

|

|

- Powered Roller Conveyor

These motorized conveyors can be placed before or after the filler station.

- Upstream, they deliver pallets from the dispenser to the filler;

- Downstream, they control the flow of filled bags and manage accumulation zones for efficient handling.

|

|

- Gravity Roller Conveyor

A cost-effective passive transport method, these conveyors rely on the weight of the bags to move them along the line.

- Typically used in between powered segments or at accumulation points.

|

|

Pallet Dispenser Integration - Automated pallet dispensers feed pallets into the filling station as needed, reducing downtime and manual intervention.

This streamlining of operations enhances worker safety by minimizing heavy lifting, ensures timely pallet placement, and supports faster production cycles overall.

|

BENEFITS OF OUR BULK BAG FILLER SYSTEMS – Why these are used instead of our Competitors

|

Economical Advantages

- Adjustable Fill Head: Easily adapts to a range of bag sizes, enhancing operational versatility and minimizing the need for multiple filling units.

- Forklift-Free Operation: An optional base compatible with pallet jacks allows for easy bag removal without the use of forklifts.

- Scalable Solutions: A variety of models ensures an ideal match between system capabilities and production budgets.

- Multi-Purpose Adaptability: Optional adapters for drums and boxes eliminate the need for separate filling systems for different container types.

- Dust Minimization: Integrated dust control features reduce material loss and lower cleanup costs.

- Automated System Integration: Fully automated solutions—with features like pallet dispensers and roller conveyors—maximize throughput, precision, and repeatable performance.

|

|

High Performance

- Precision Weighing: Integrated load cells ensure accurate fills, preventing overfills and wasted material.

- Bag Stability During Fill: Vibration-assisted densification and deaeration compacts material for stable, high-weight fills, improving transport safety.

- Bag Pre-Inflation: Built-in bag inflator removes folds and creases, promoting even filling and efficient material flow.

- System Integration: Customizable controls synchronize the filler with upstream and downstream processes, accelerating filling cycles and reducing downtime.

- Operator Efficiency: Automated bag loading and discharge systems reduce manual handling, minimizing physical strain and boosting overall productivity.

|

|

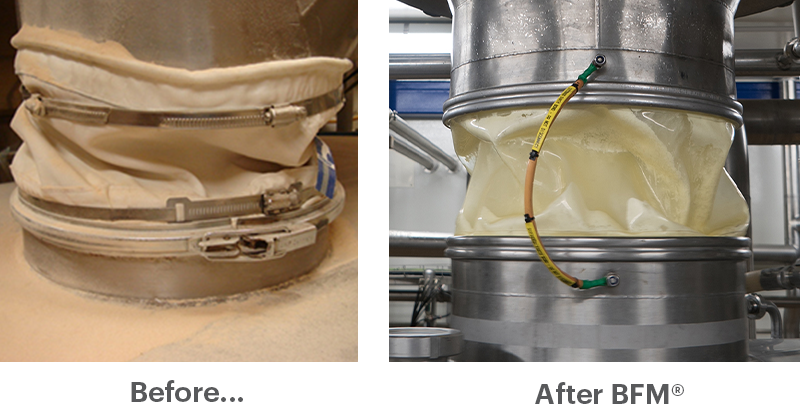

Clean Operation

- Sealed Fill Collar: An inflatable collar tightly secures the bag inlet to contain dust and prevent leakage.

- Air Venting and Dust Capture: Vent ports allow for air displacement and easy dust extraction, keeping the environment clean and safe.

- Spill Prevention: The densification platform stabilizes filled bags, reducing the chance of tipping or material spillage.

- Sanitary Design Options: Stainless steel construction is available for applications requiring hygienic processing, such as food or pharmaceutical production.

|

Options & Configurations

|

Weighing Systems - Flexicon fillers can incorporate load cells for weighing bags directly during the filling process. Alternatively, a pre-weigh hopper installed above the filler allows material to be weighed in advance. This setup improves efficiency by enabling one bag to be filled while the hopper is reloaded for the next cycle.

|

Control Systems and Automation - Programmable logic controllers (PLCs) and human-machine interfaces (HMIs) can be integrated to automate the filling process. These advanced systems allow operators to set and monitor key parameters, enabling the coordination of multiple fillers—either independently or simultaneously—even when handling different materials or bag styles.

|

|

Filling for Alternate Containers - Flexicon’s systems can also be adapted to fill drums, boxes, or other containers. Adjustable fill heads, integrated dust control systems, and automated indexing features allow for the sequential filling of multiple containers on the same pallet, expanding operational flexibility.

|

Low-Profile for Pallet Jack Access

For facilities without forklift access, low-profile designs allow filled bulk bags to be removed using standard pallet jacks. This feature improves convenience and reduces equipment requirements.

|

|

Sanitary Design Options - For food, pharmaceutical, or dairy applications, sanitary configurations are available. These fillers feature stainless steel construction, continuous welds, and enclosures rated for wash-down environments, meeting stringent standards such as 3-A and USDA Dairy compliance.

|

Mobile Filling Units

Mobile models offer a compact footprint and are easy to move between production areas. This portable option reduces the need for multiple stationary units and allows flexible use throughout a facility.

|

|

Gravity-Based Filling - When equipped with overhead weigh hoppers, gravity-fed bulk bag filling systems can pre-measure material before release into the bag. This allows the next bag to be prepped while the hopper is being refilled, streamlining throughput and improving accuracy.

|

Wide Inlet Filler - For Chunks and Semi-Solids

This model allos for passage of large, moist or dense chunks and semi-solid materials into open top or duffle top bulk bags or super sacs.

|

|

Explosion Protection Considerations- We can offer CSA XP rated motors and electrical enclosures if required. Please let us know if you have an application that would have this requirement.

Do you have your KST and Pmax values of your material ready? This is a key piece of information for this topic.

|

|

|

Featured Case Study: Mayorga Organics

MIAMI, FL — Mayorga Organics, known for its sustainable, direct-sourced coffee from Latin American farmers, opened a 42,000 sq. ft. Miami facility to produce its signature Café Cubano Roast.

To streamline production, they installed a Flexicon bulk handling system including two bulk bag dischargers, three flexible screw conveyors, and a bulk bag filler.

Roasted beans from the roaster are loaded into bulk bags, discharged into a hopper, and conveyed to a grinder. Ground coffee is then conveyed to a bulk bag filler. Later, filled bags are discharged into another conveyor feeding the packaging line.

Level sensors and PLC automation regulate material flow, ensuring clean, efficient, and scalable operations. Flexicon's system helped Mayorga maximize space, improve cleanliness, and prepare for future growth.

|

|