FLEXIBLE SCREW CONVEYOR SYSTEMS

QUOTE REQUEST | Product Video | Quick Ship (approx 3 weeks) | Spare Parts Inquiry

|

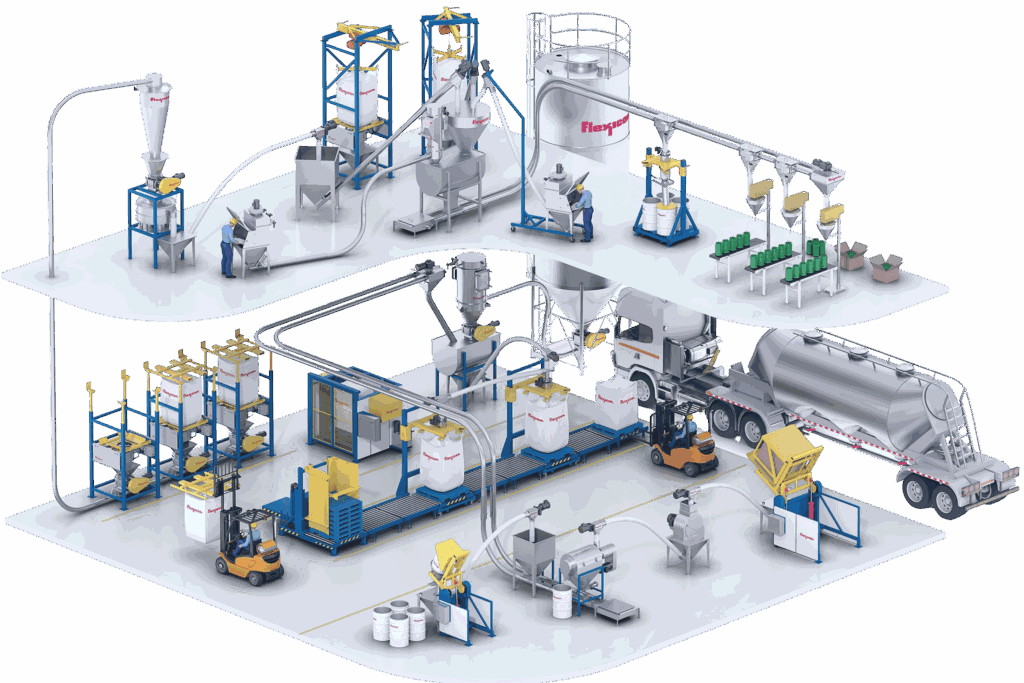

At Rate Technology Systems, we are the exclusive Canadian representatives of Flexicon®, a global leader in dry bulk material handling solutions. With over 25,000 installations worldwide, Flexicon’s Flexible Screw Conveyors are proven to move virtually any type of bulk material—whether it’s a free-flowing or a challenging, cohesive product.

These conveyors are engineered for maximum layout flexibility, capable of operating horizontally, vertically, or at any incline, while navigating around existing equipment and structural constraints—ideal for optimizing tight plant footprints.

And with just one moving part, they offer reliable, low-maintenance operation, minimizing downtime and reducing total cost of ownership.

Whether you're feeding packaging lines, mixing vessels, or storage bins—Flexicon® delivers performance you can count on.

Send us a Quote Request, and let us help you engineer the right solution for your plant.

Yes, we are able to offer 575v and CSA certs on motors and electrical components!

|

|

How Does this System work?

A Flexicon® Flexible Screw Conveyor uses a rotating helical steel screw housed inside a smooth conveying tube, with no internal bearings or seals in the product flow area. The screw is driven by an electric motor mounted at the discharge end, moving material smoothly and efficiently from the feed point to the discharge location. These are idea lfor short to medium convey distances, and one of the most economical methods of conveying dry bulk powders and solids.

|

Multiple intake Options

The inlet of a flexible screw conveyor is equipped with a charging adapter that can be easily connected to a hopper, bulk bag discharger, bag dump station, or other upstream process equipment.

To ensure consistent feeding of difficult or non-free-flowing materials, a range of vibratory and mechanical flow-assist options can be incorporated to help move product smoothly into the conveyor.

|

|

Durable Flexible Screw Design - The flexible screw is the sole moving component in contact with the material, engineered to reliably convey both free-flowing and difficult bulk solids that may pack, cake, or smear—without causing segregation of blended products.

Designed to operate at full fill, its self-centering construction promotes smooth, efficient conveying while protecting product integrity, regardless of particle size or fragility.

|

|

Optimized Screw Geometry - Bulk materials vary widely in shape, size, flow behavior, and bulk density.

Flexicon offers an extensive selection of screw geometries tailored to handle virtually any material.

Whether a product tends to pack, cake, smear, plug, fluidize, or interlock, there is a Flexicon screw design suited to the application.

|

|

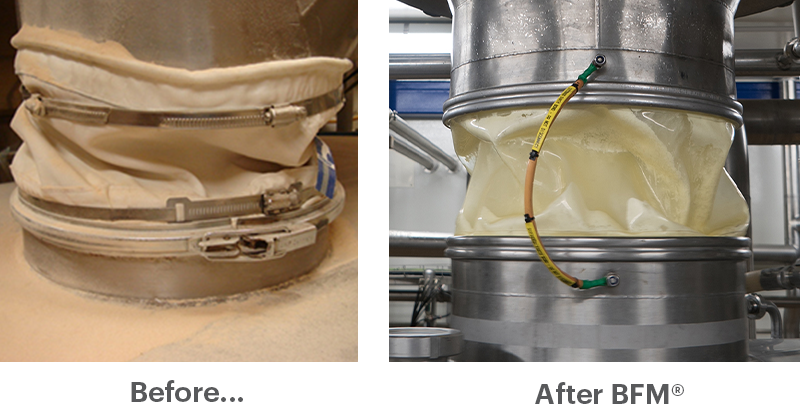

Enclosed Conveyor Tube - We offer flexible plastic, rigid plastic, or carbon/stainless steel tubing that can be routed at virtually any angle, forming a fully enclosed system to control dust emissions.

A convenient clean-out cap allows fast emptying and wash-down.

Because there are no internal seals or bearings in contact with the material, the only moving component in the flow path is the flexible screw itself.

|

|

Efficient Conveyor Drive - The compact drive system is positioned at the discharge end of the conveyor—above the product flow—eliminating the risk of material contacting bearings or seals.

This end can be suspended by chain or cable, mounted on structural supports, or directly connected to downstream equipment or vessel rims, making it ideal for tight or custom-fit spaces.

|

BENEFITS OF FLEXIBLE SCREW CONVEYOR SYSTEMS – Why These are used instead of other Convey Methods

|

Simple, Economical, and Effective - As the exclusive Canadian representatives of Flexicon®, we’re proud to offer a conveying solution that’s cost-effective and uncomplicated. Flexicon® Flexible Screw Conveyors eliminate the costly complexity of traditional systems by forgoing the use of internal bearings, chains, cables, or seals within the product stream. With a single moving part—a robust, flexible screw—the system delivers unmatched reliability, long service life, and minimal maintenance. Being known for the ability to constantly start and stop under full load, this method of conveying is relied upon by every industry that handles dry bulk solids – powders/dust/granules/pellets and much more.

The tube and screw can be routed in virtually any direction, giving you full flexibility in design, even where space is limited or unconventional paths are required.

Streamlined Design with Just One Moving Part - Only one component contacts the material: a rugged flexible screw powered by an electric motor. As the screw rotates, it propels product forward while automatically centering itself in the tube—eliminating the need for additional mechanical parts like chains, cables, disks, or internal bearings that are common in alternative conveyors. This reduces potential failure points, simplifies maintenance, and minimizes contamination risk.

Built for Reliability, Minimal Maintenance - These conveyors are designed with uptime in mind. There are no internal parts that typically wear out—no chains, belts, filters, or buckets. Even under challenging conditions, such as handling some moist or dense products, Flexicon conveyors can start, stop, and restart without jamming or damage. This consistent performance reduces downtime and maintenance costs.

|

|

True Conveying Flexibility - Flexicon® conveyors outperform systems with rigid paths and limited incline capabilities. Materials can be moved horizontally, or at any angle—navigating around obstacles or through tight spaces. Whether you're working in a confined area or integrating with existing process equipment, these conveyors provide unmatched layout flexibility.

Gentle on Products, Great for Blends - The system’s design preserves the integrity of delicate products and blends. The screw moves materials smoothly without grinding or separating mixed components. The self-centering rotation ensures controlled, gentle handling throughout the entire conveying process.

|

|

Fully Enclosed for Clean Operation - Dust, mess, and contamination are non-issues with Flexicon®’s enclosed tube design. This sealed system keeps the product contained, protecting both the product quality and plant environment. It also maintains consistent moisture and temperature levels, which is essential for sensitive materials.

Easy to Clean, Fast Turnaround - Thanks to the smooth tube interior and absence of internal obstructions, cleanup is quick. Just remove the clean-out cap, reverse the screw to discharge any residual material, and rinse with air, water, steam, or approved cleaners—making it a great choice for facilities with strict sanitation protocols.

|

Options & Configurations

|

Hopper Flow Enhancement Systems

To assist with challenging materials, Flexicon provides optional flow-assist technologies.

This includes:

-hopper wall vibrators,

-mechanical agitators

-aeration pads

Each are designed to promote consistent material movement and prevent flow interruptions that might cause ratholing, bridging, and more

|

|

Mobile Configurations for Plant-Wide Flexibility

All Flexicon flexible screw conveyors can be mounted on caster-equipped frames with vertical support masts, allowing operators to easily move equipment throughout the facility for versatile, on-demand material transfer wherever it’s needed. |

|

Sanitary & Industrial Finishes Available - Whether you're in food, pharma, or heavy industry, there’s a Flexicon® configuration for your standards. Units are available in carbon steel with durable coatings or in stainless steel with finishes that comply with food, dairy, or pharmaceutical regulations—including options designed to meet 3-A Sanitary Standards. Casings are standard UHMW food grade material, and we also offer a carbon steel outer tube for heavy duty applications.

3A Sanitary Option - 316 SS

|

HD Option with Steel Tube

|

Standard in Carbon Steel

|

|

|

Explosion Protection Considerations- We can offer CSA XP rated motors and electrical enclosures if required. Please let us know if you have an application that would have this requirement. Do you have your KST and Pmax values of your material ready? This is a key piece of information for this topic. |

|

Where Can These Flexible Screw Conveyors Be Used?

|

|

Bulk Bag Discharging

Bulk bags or super sacs typically discharge material in large volumes quickly due to gravity.

A flexible screw conveyor allows that flow to be metered and regulated, preventing downstream equipment (such as a mixer, tank, silo, bin, hopper, screener, etc.) from becoming overwhelmed.

It acts as a buffer between the bag’s large, uncontrolled discharge and the precise needs of the next step in the process.

|

|

|

Bag or Container Dump Stations

Dumping material from bags or containers introduces non-uniform material flow due to clumping, bridging, or inconsistent feeding rates.

A flexible screw conveyor downstream of a dump station regulates the flow to ensure smooth, controlled discharge into process lines, prevents surging or starvation in downstream equipment.

It also converts batch-style dumping into a consistent, metered feed.

|

|

|

Gravimetric and Volumetric Feeder Refill

Gravimetric and volumetric feeders often rely on flexible screw conveyors for a critical reason: they require a consistent and controlled supply of bulk material to maintain accurate feeding and dosing

This is a common application for a Flexicon flexible conveyor.

|

|

|

Volumetric Feeding

If a tight accuracy is NOT required, a flexible screw conveyor can simultaneously act as a volumetric feeder when you calibrate and control its screw speed to dispense a consistent volume of material per unit time.

It’s a smart, streamlined solution for plants that need simple, repeatable bulk material dosing—without the cost or complexity of adding a dedicated feeder.

|

|

|

Conveyors to/from:

-Silos

-Hoppers

-Bins or Surge Bins

-Screeners

-Mixers

-Size Reduction equipment

-Dust Collector discharge

-and more

|

Featured Case Study: Goya Foods

DORAL, FL — Sazon, Inc., a manufacturing division of GOYA Foods, produces bouillon powders and Sazón GOYA® seasoning blends. As production volumes increased, the company sought to eliminate the labor‑intensive process of manually dumping dozens of 50‑lb bags into ribbon blenders for each batch.

To support growth, Sazon installed five automated bulk weighing and batching systems—one per blender—engineered by Flexicon. Each system integrates a BULK‑OUT® bulk bag discharger, flexible screw conveyor, and PNEUMATI‑CON® pneumatic conveying line to accurately batch and transfer high‑volume ingredients directly to the blenders.

The automated system uses load cells and PLC controls to precisely measure batch weights, eliminate manual handling, and maintain dust‑tight operation. Finished blends are then packaged at high speed, producing up to 1,500 packets per minute.

As a result, Sazon increased output from 21 to 35 batches per shift, reduced labor demands, eliminated operator fatigue, and now packages over one billion seasoning packets annually—with greater efficiency, consistency, and safety.

|

|