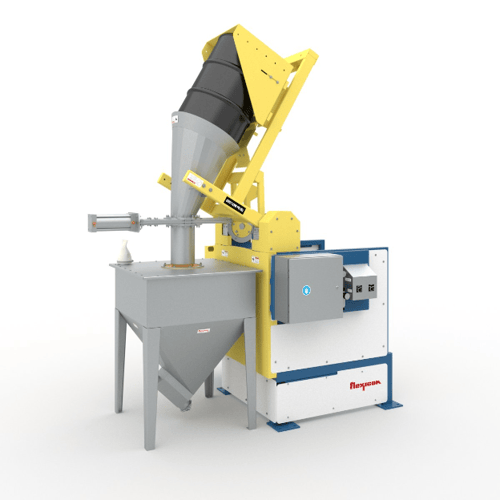

DRUM/BOX/CONTAINER DUMPER SYSTEMS

QUOTE REQUEST | PRODUCT VIDEO | Spare Parts Inquiry

|

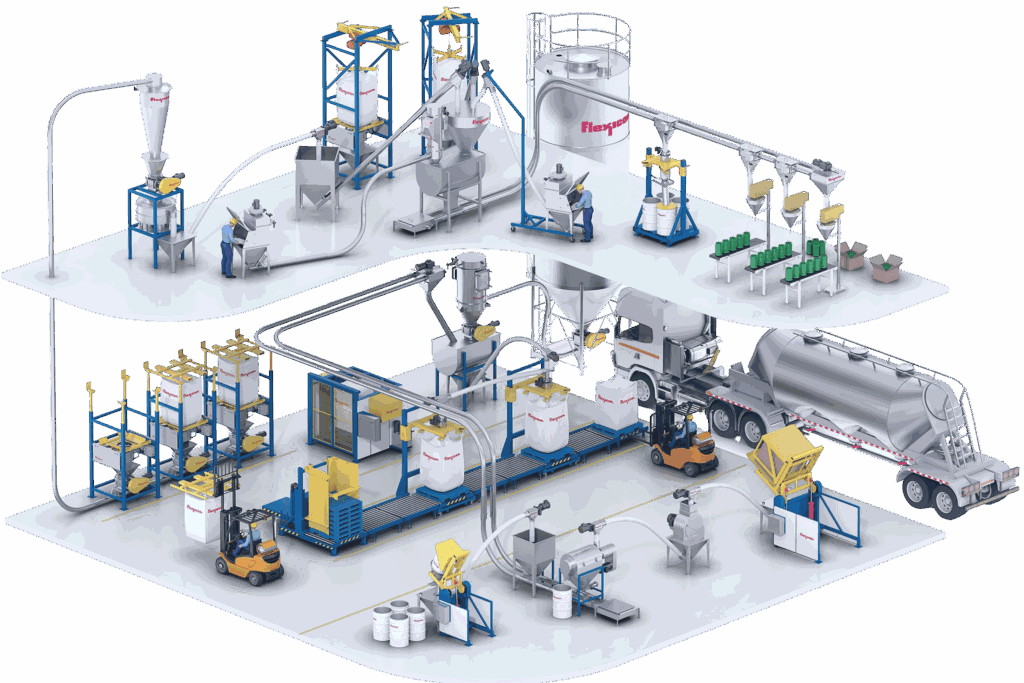

At Rate Technology Systems, we are the exclusive Canadian representatives of Flexicon®, a global leader in dry bulk material handling solutions.

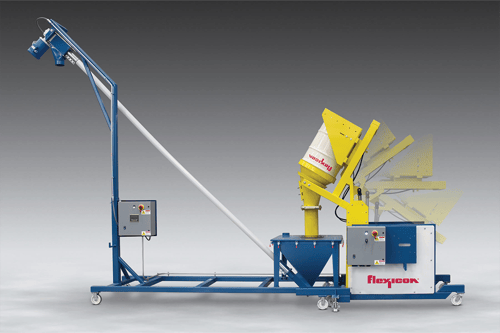

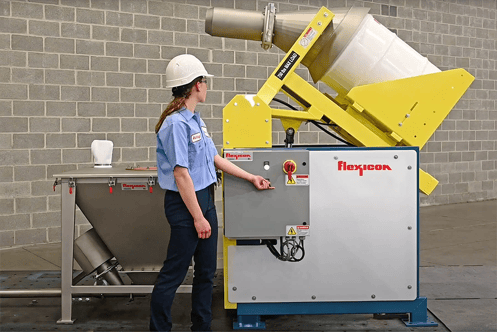

Dust-Free, Efficient Material Unloading - Flexicon’s TIP-TITE® and Open-Chute Dumpers offer a safe and effective solution for unloading bulk materials from drums, boxes, and containers—without releasing dust into your facility.

These systems integrate seamlessly with downstream equipment, improving operational flow, safety, and labor efficiency.

Send us a Quote Request, and let us help you engineer the right solution for your plant.

Yes, we are offer 575v and CSA certs on motors and electrical components!

|

|

Available Models

|

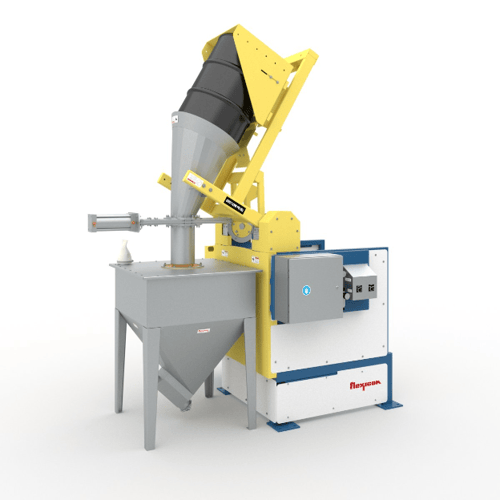

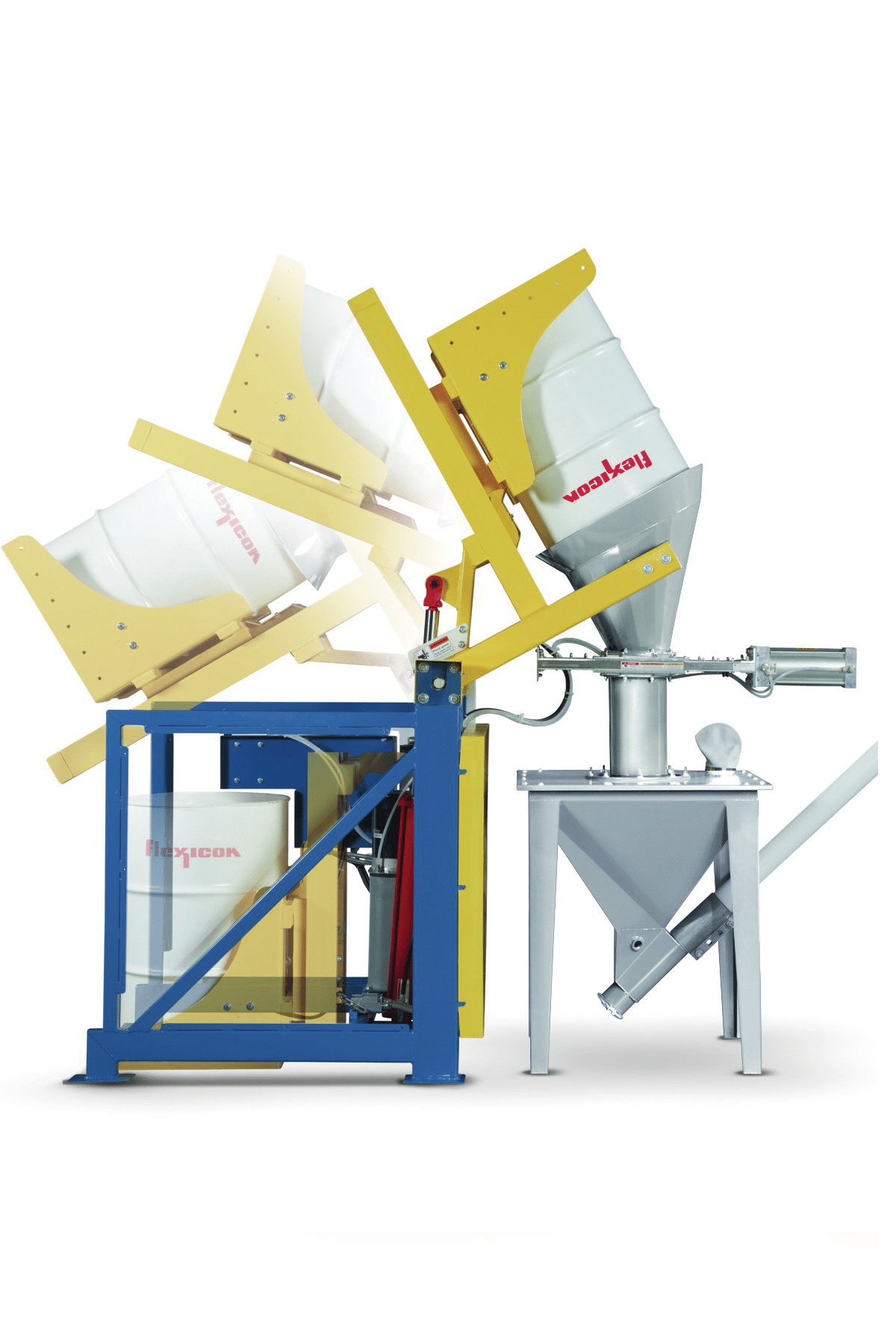

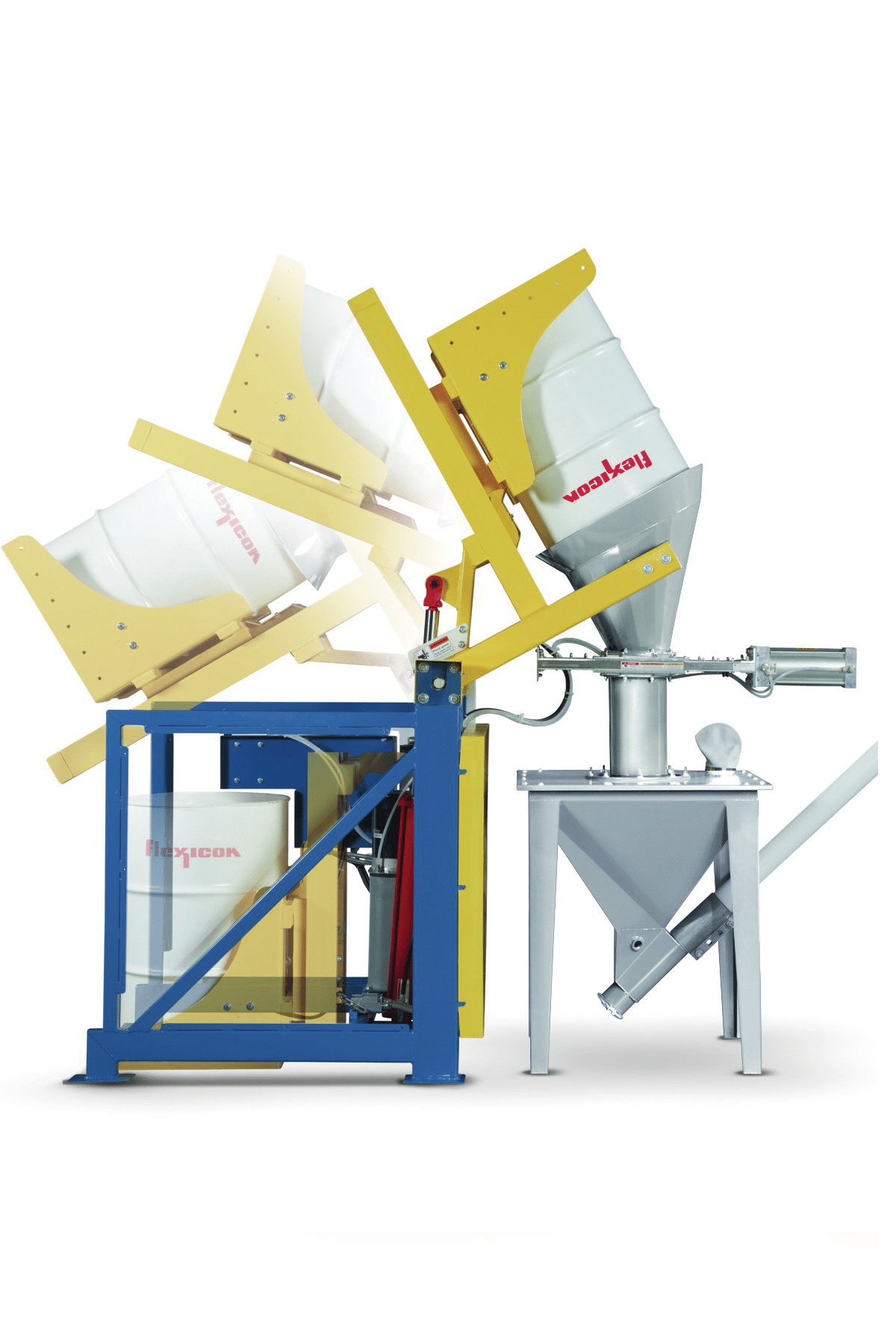

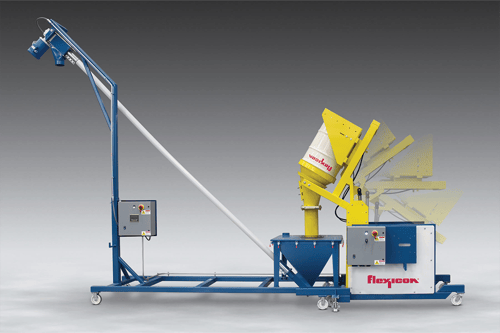

Drum Dumpers

Engineered to form a dust-tight seal between the drum and the discharge cone, these units lift and tip drums using hydraulic cylinders, allowing either dust-free or open transfer of material into downstream processes.

|

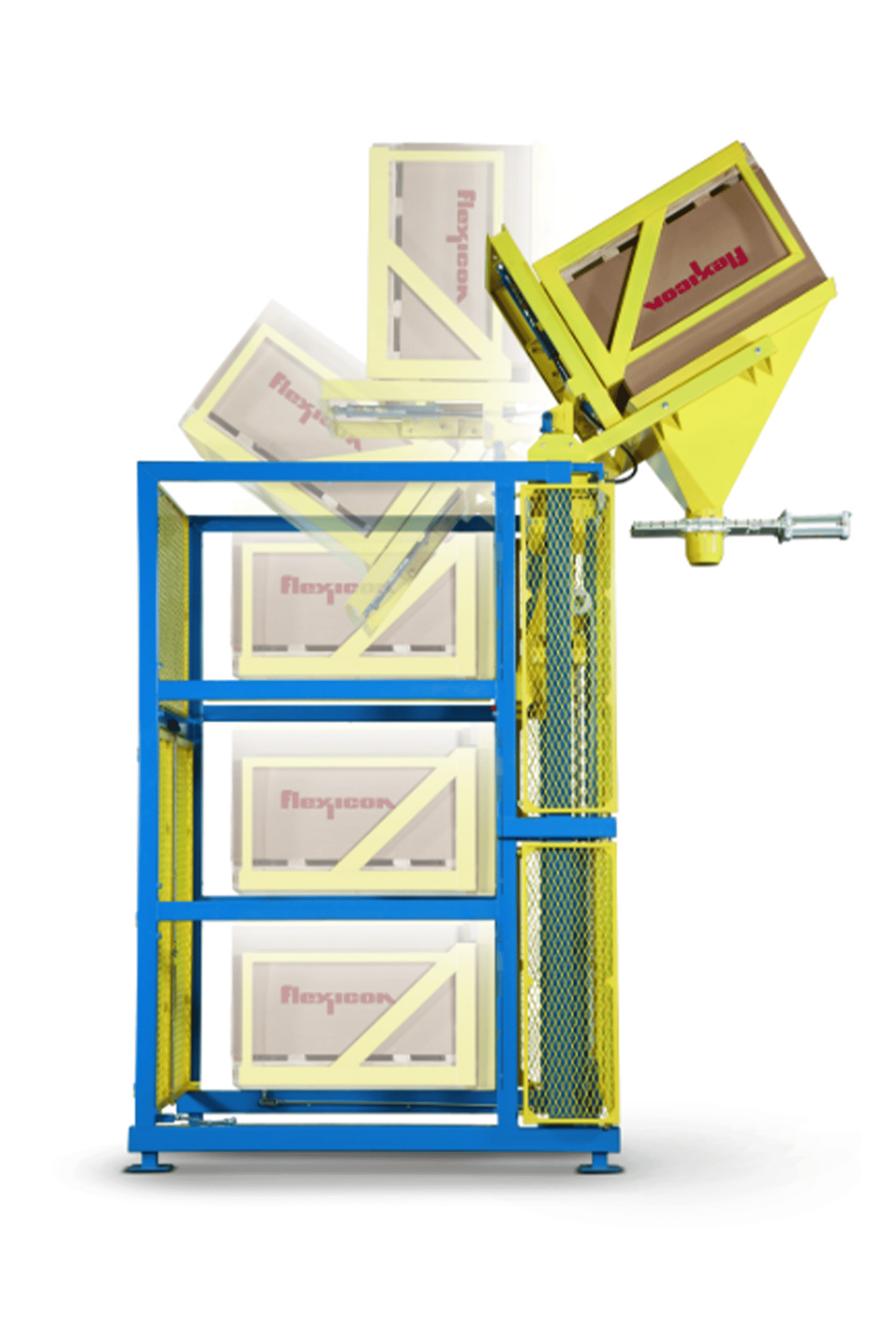

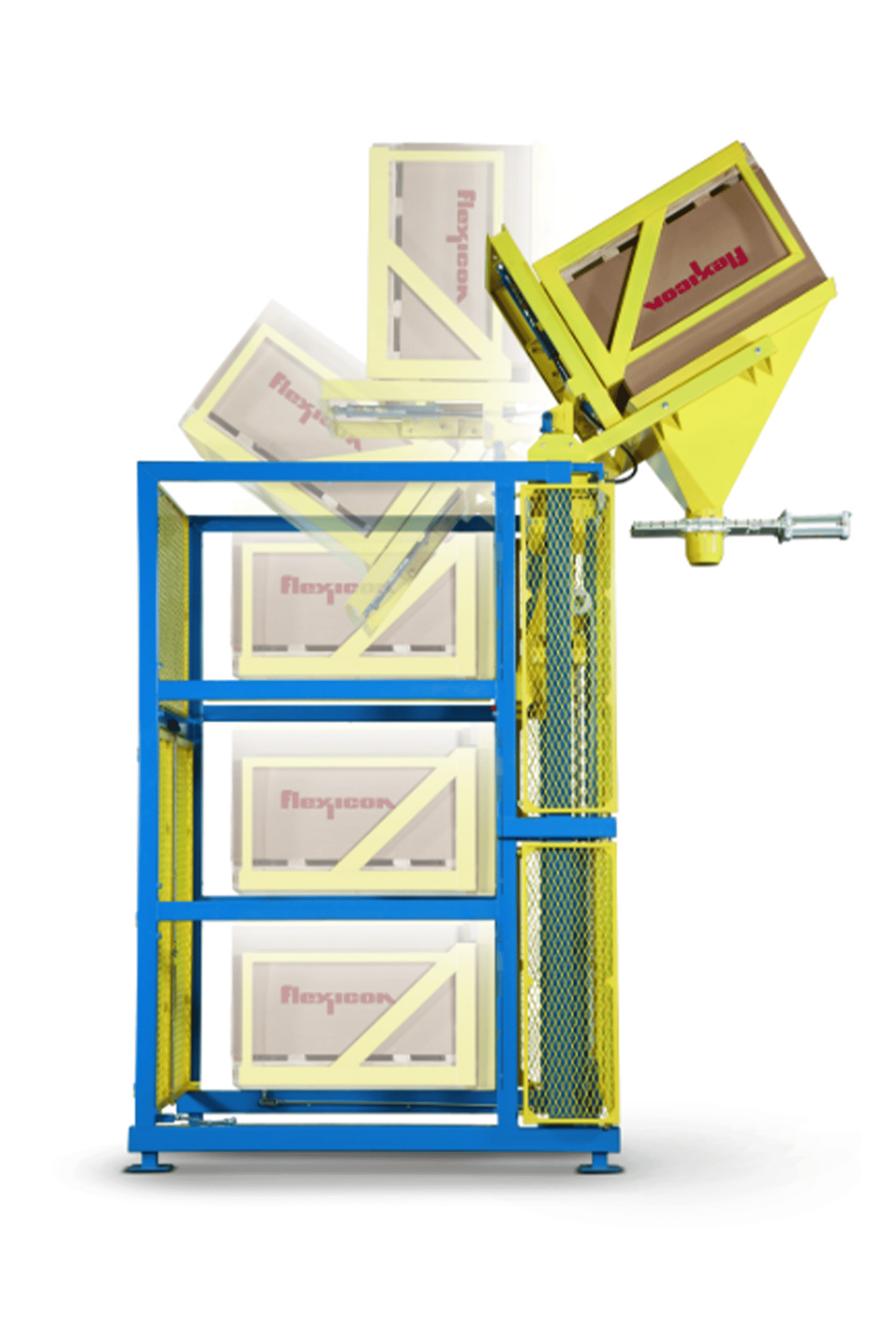

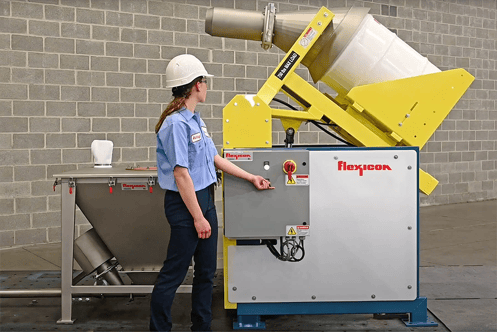

Box/Container Dumpers

Ideal for Gaylords or similar containers, these models secure the box against a discharge hood before tilting for controlled material release. Both dust-sealed and open-chute configurations are available.

|

High-Lift Dumpers

These units are designed for facilities that discharge into elevated vessels (up to 10 ft high). They lift and tilt containers from floor level, making them perfect for gravity-fed systems and raised equipment.

|

How does this system work?

|

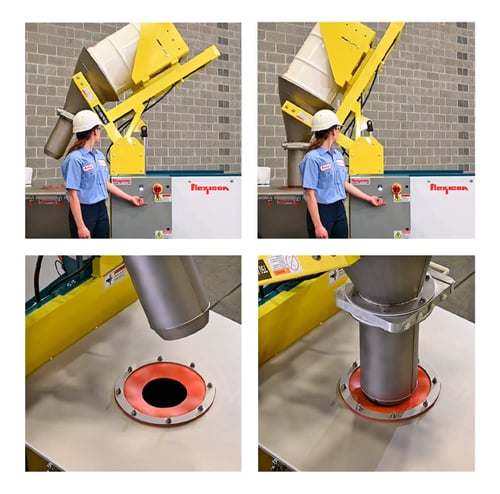

Loading: The container is placed at floor level on the dumper’s platform.

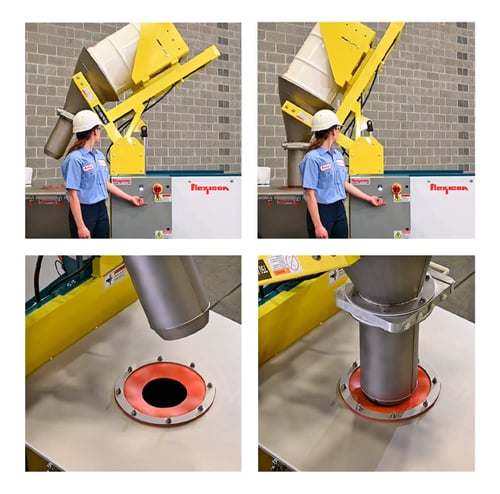

Sealing: A hydraulic lift raises the container until it seals against a discharge cone, creating a dust-tight barrier.

Tilting: A separate hydraulic system tips the container and hood assembly to a preset angle (usually 45°, 60°, or 90°) for complete material flow.

Discharge: In TIP-TITE® models, a slide gate valve opens once the seal is complete, enabling dust-free transfer. Open-chute models omit the valve for less critical applications.

|

Container Platform

Lifts and tilts the container with precision, forming a sealed connection with the discharge cone.

|

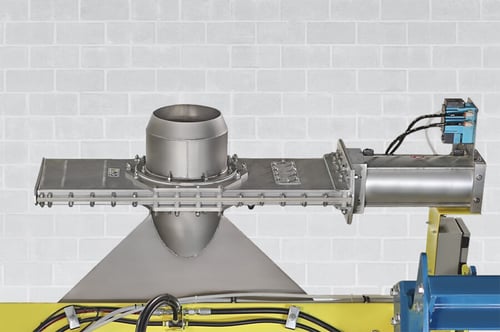

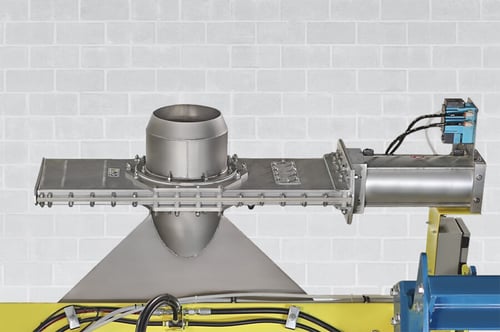

Discharge Cone

Forms a secure connection with the receiving vessel to prevent dust emissions during material transfer.

|

Hydraulic Tilt System: Offers smooth, controlled motion and durability for continuous use.

|

Slide Gate Valve: On TIP-TITE® systems, enables precise, dust-free discharge control.

|

Optional Features

|

Mobile Dumpers: Mounted on wheels and equipped with leveling jacks, these units can be moved to different locations for flexible use across your plant.

|

Sanitary Designs: Made from stainless steel with polished welds and sloped horizontal surfaces, these models meet the hygiene standards of food, pharmaceutical, and chemical industries.

|

Custom Options: Tailored for special materials, volumes, or container types—including pails, totes, or multiple-unit discharge. Configurable to integrate with conveyors, batching systems, or elevated vessels.

|

|

|

BENEFITS OF CONTAINER DUMPER STATION SYSTEMS – Why These are used

|

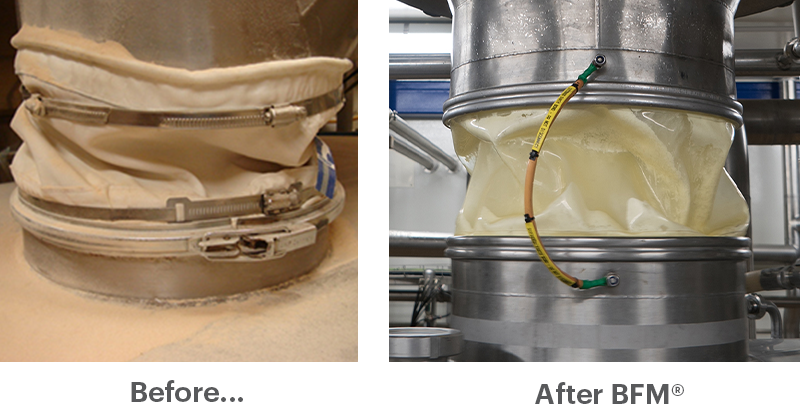

Dust-Free Material Handling

TIP-TITE® Dumpers are designed to eliminate dust at the source by lifting and sealing containers against a discharge cone.

With tight gasketted connections and controlled release through manual or pneumatic slide gates, materials are fully enclosed—protecting workers, surrounding equipment, and the facility from contamination.

|

|

Improved Workplace Safety

By eliminating the need for manual dumping, TIP-TITE® Dumpers reduce physical strain and minimize exposure to hazardous dust.

Their automated operation and built-in safeguards help maintain compliance with safety regulations while creating a safer, more ergonomic working environment.

|

|

Reliable, Heavy-Duty Performance

Built for continuous use in demanding applications, these systems feature rugged construction and precision components to ensure long-lasting, consistent operation.

|

|

Boost Efficiency and ROI

With smooth, controlled, and dust-free operation, TIP-TITE® Dumpers streamline repetitive dumping tasks, reduce labor needs, and minimize downtime.

Their dependable performance leads to lower operating costs and a faster return on investment.

|

Where Can These Container Dumpers Be Used?

Flexible Screw Conveyors - Perfect for short- to medium-range material transfer, these dumpers can discharge directly into flexible screw conveyors for reliable, contained handling.

|

Pneumatic Conveying Systems - Integrate easily with pneumatic systems for clean, enclosed movement of bulk materials to distant processing or storage points.

|

Tubular Cable Conveyors - Ideal for gentle handling, TIP-TITE® Dumpers pair well with tubular cable conveyors, preserving product integrity over long distances.

|

Gravity-Fed Processes - High-lift configurations make it easy to discharge materials into elevated vessels, supporting gravity-based feed systems in downstream equipment.

|

Featured Case Study: Bakery On Main

Bakery On Main Automates Gluten-Free Production with Flexicon Conveying System

To meet growing demand for gluten-free products, Bakery On Main built a new 110,000 sq ft facility featuring fully enclosed, automated bulk handling systems from Flexicon. The previous open, labor-intensive system using incline belts was replaced with two integrated FLEXI-DISC® Tubular Cable Conveyor systems — one for granola, one for oatmeal.

Granola Line Highlights:

-

Major ingredients are bulk-dumped and conveyed via a 102 ft TCC to mixers.

-

Minor ingredients are added manually for precision.

-

Finished granola is conveyed to packaging machines, with excess recirculated using a TIP-TITE® Box Dumper.

Oatmeal Line Highlights:

-

All ingredients are unloaded from bulk bags, conveyed through a 36 ft TCC system, blended, and then packaged.

-

A second TCC circuit feeds a second packaging line.

Benefits:

-

Fully enclosed to prevent contamination.

-

Space-saving ceiling-mounted layout.

-

PLC-controlled automation improves efficiency and reduces manual labor.

-

System flexibility allows for future growth without additional labor.

Owner Michael Smulders reports zero maintenance issues in the first year and improved batch time, worker ease, and ingredient protection.

|

|