PNEUMATIC & VACUUM CONVEYOR SYSTEMS

QUOTE REQUEST | Product Video | Spare Parts Inquiry

|

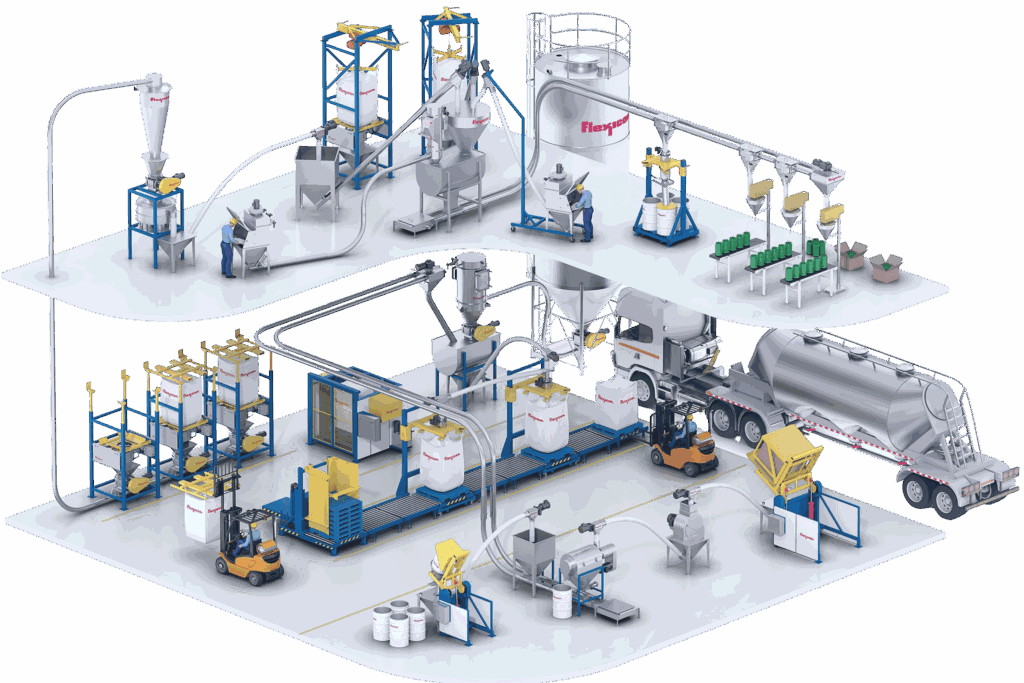

At Rate Technology Systems, we are the exclusive Canadian representatives of Flexicon®, a global leader in dry bulk material handling solutions.

Pneumatic & Vacuum conveyors move bulk solids—like powders, granules, and small particles—through enclosed tubing using a stream of positive pressure or negative vacuum air. Flexicon’s PNEUMATI-CON® systems utilize dilute phase technology and are individually designed to suit a wide variety of applications. These systems allow for flexible layout configurations and are capable of conveying materials both horizontally and vertically over various distances.

Send us a Quote Request, and let us help you engineer the right solution for your plant.

Yes, we are offer 575v and CSA certs on motors and electrical components!

How Does this System work?

Positive Pressure Conveying Systems - Positive pressure dilute phase systems are typically used when moving bulk materials over greater distances or when higher capacity is required. These systems use a positive displacement blower to generate airflow, pushing materials through one or more downstream entry points, where product is introduced via rotary airlock valves. This maintains the pressure difference necessary for conveying. The material-air mixture exits at use points where separation occurs via cyclone separators or filter receivers, or is fed straight into process vessels connected to downstream dust collectors. These systems are energy-efficient for long-distance runs and can discharge directly into receiving equipment without requiring additional rotary valves at the endpoint.

|

|

|

Vacuum Conveying Systems - Vacuum dilute phase pneumatic systems are well-suited for transferring materials from multiple infeed points—like storage silos, production equipment, trucks, or railcars—to one or more destinations. They provide excellent containment and minimal heat exposure, making them ideal for handling sensitive or hazardous substances. A vacuum pump located downstream generates negative pressure within the conveying line, enabling material to be drawn in through devices such as rotary airlocks, flexible screw feeders, suction wands, or flood feed hoppers. Discharge is typically accomplished via filter receivers or cyclone separators positioned above processing equipment or storage bins. These systems also allow direct transfer into closed vessels like blenders or reactors under vacuum, eliminating the need for localized dust collection at each discharge point.

|

|

System Components

|

Diverter Valves and Flow Routing Solutions - Flex-tube, wye, and fill/pass diverters enable smooth and selective flow transitions within a pneumatic conveying line. These components allow for tailored system layouts, helping route materials from various sources to one or more destinations. Fill/pass diverters support inline material movement along a continuous path, while flex-tube and wye diverters offer multi-directional routing. Strategically implemented, these diverters optimize system flexibility and efficiency across any plant configuration. |

|

Rotary Airlock Valves – Versatile and Pressure-Tight - Rotary airlocks ensure consistent feeding of bulk solids into or out of pneumatic conveying lines, while maintaining an airtight seal between zones of differing pressures. Positioned at material entry points, they regulate flow into the system, ensuring steady throughput and stable pressure. At discharge points, they allow continuous unloading during operation.

Available in a broad range of sizes and designs, these valves are adaptable to varying material types and flow capacities.

|

|

Filter Receivers – For Precise Separation - PNEUMATI-CON® filter receivers are engineered to provide high-efficiency air/material separation across all throughput levels. Smaller models are suited for placement above process machines or packaging lines in space-limited setups.

Medium- and high-capacity versions integrate with larger process vessels like blenders or bulk bag fillers, supporting clean, dust-free operation throughout the system.

|

|

Cyclone Separators – Filterless Particle Removal - Cyclone separators separate solids from a conveying air stream without the need for filters. Using centrifugal force, the incoming air and material mixture spins inside the chamber, forcing heavier particles to the outer wall and downward into a discharge outlet.

This method provides reliable, low-maintenance performance for a wide range of flow capacities.

|

|

Storage Vessels – Silos and Day Bins - Silos, day bins, and similar storage containers offer durable, dependable holding capacity for bulk materials ahead of downstream operations.

Constructed from carbon or stainless steel with industrial or sanitary finishes, these vessels are designed for seamless integration into pneumatic conveying systems.

|

|

Hand-Held Pick-Up Wands – Manual Feeding - These ergonomic tools allow operators to manually draw materials into vacuum conveying systems from drums, boxes, or other portable containers.

Ideal for mobile or small-batch setups, they provide flexible, on-demand material intake.

|

|

Automation and System Controls - Flexicon’s systems include integrated electrical and control panels to automate material flow operations.

These controls can manage diverter valve timing, flow rates, and system sequences through manual input, timers, or weight-based triggers—ensuring accuracy, efficiency, and ease of use across diverse applications.

|

BENEFITS OF PNEUMATIC/VACUUM CONVEYOR SYSTEMS – Why These are used instead of other Convey Methods

|

VERSATILITY

Flexible Routing & Layout Adaptability - PNEUMATI‑CON® pneumatic systems are designed to integrate seamlessly into existing facilities. They convey material vertically or horizontally, navigate tight spaces, and pass through small openings—making them ideal for complex or space‑constrained plant layouts.

Long‑Distance Transfer Capability - Engineered for reliable bulk material transport over extended distances, these systems deliver consistent performance while minimizing downtime.

Multiple Infeed & Discharge Points - A single PNEUMATI‑CON® system can serve multiple pick‑up and discharge locations, enabling efficient material distribution and flexible process routing across diverse applications.

|

|

|

CAPABILITY

Complete Material Transfer with Zero Residue - PNEUMATI-CON® systems are engineered for total evacuation of both the source vessel and the conveying line. This minimizes cross-contamination between materials, making them especially effective for batch operations where ingredient purity and delivery precision are essential.

Handles a Broad Range of Materials - From powders of various bulk densities to flakes, pellets, capsules, and tablets, Flexicon pneumatic conveyors are designed to manage a wide variety of product forms, enabling multi-ingredient handling with a single system.

Scalable Throughput - Whether feeding a compact packaging station or supplying bulk to silos and railcars, PNEUMATI-CON® systems are capable of managing flow rates from a few pounds per hour to multiple tons. Their design helps maintain consistent performance, even under variable feed conditions.

|

|

|

CLEANLINESS

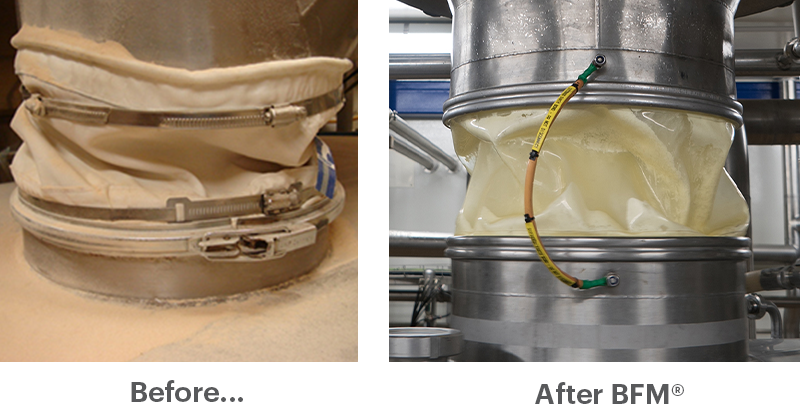

Sealed Conveying for Contamination Control - The fully enclosed design of PNEUMATI-CON® systems keeps both the conveyed product and the processing environment free from dust and contamination. This is especially valuable when handling fine or hazardous powders.

Low-Maintenance Access and Sanitation - Built for user convenience, the system includes filter receivers with easy-access panels and optional features like rotor support bars for rotary airlocks—streamlining cleaning and reducing maintenance time. Flexible screw conveyors can also be integrated to meter materials into vacuum systems with minimal upkeep.

Engineered for Industrial and Sanitary Compliance - Constructed in either rugged carbon steel or stainless steel for sanitary environments, PNEUMATI-CON® systems are tailored to meet the demands of industries such as food, dairy, and pharmaceuticals, with options available for compliance with strict cleanliness and hygiene standards.

|

|

Where Can These Pneumatic/Vacuum Conveyors Be Used?

|

|

Bulk Bag Dischargers

Pneumatic conveying systems provide an efficient and dust-controlled method for transferring materials discharged from bulk bags or super sacs to subsequent process stages.

They maintain a steady material flow while minimizing airborne particles.

|

|

|

Bag Dump Stations

When integrated with a bag dump station, pneumatic conveying systems offer a streamlined and clean way to introduce materials into the process line.

The enclosed system reduces dust exposure and promotes a safer, cleaner working environment.

|

|

|

Weigh Batching Systems

Ideal for precision and flexibility, pneumatic conveying enables accurate delivery of pre-weighed materials across long distances.

This supports versatile plant layouts and ensures reliable material dosing to downstream equipment.

|

|

|

Batching and Blending Systems

Pneumatic conveyors can deliver multiple ingredients from various locations to mixers or blenders.

This setup ensures uniform ingredient flow, allowing for precise recipes and consistent product outcomes.

|

|

|

Truck and Railcar Loading/Unloading

Pneumatic systems offer fully enclosed, dust-tight transfer of bulk solids during truck or railcar operations.

This reduces material loss, enhances site cleanliness, and ensures safe, efficient material handling during transit.

|

Featured Case Study: LKAB Minerals

LKAB Replaces Mechanical System with Pneumatic Solution for Wet Mica

At its Derby, UK facility, LKAB Minerals has processed muscovite mica since the 1950s for use in various industries. To safely move hot, abrasive, wet mica powder from a lower floor to a dryer above, LKAB replaced its worn mechanical conveyors with a pneumatic vacuum conveying system from Flexicon.

The system transfers mica 11 meters vertically and 30 meters horizontally via a 3" diameter line into a filter receiver. The setup includes a floor hopper, flexible routing, and a 15 kW vacuum pump. It overcomes space constraints and abrasive wear, with features like a reverse-pulse filter cleaner and improved elbows to extend component life.

Despite initial challenges, the new system streamlined operations, reduced worker exposure to heat and heavy lifting, and provided a more reliable, low-maintenance conveying solution.

|

|