BUILDING THE HIGHEST QUALITY INDUSTRIAL FANS IN NORTH AMERICA FOR SIX GENERATIONS

CSA APPROVED! - Heavy Duty - 575v Options

Capable of testing in a 12ft 50,000 CFM @ 24"wg test chamber

5 YEAR FULL WARRANTY

CSA APPROVED! - Heavy Duty - 575v Options

Capable of testing in a 12ft 50,000 CFM @ 24"wg test chamber

5 YEAR FULL WARRANTY

At Hartzell, they’ve understood the importance of clean air long before it became a global conversation. Since engineering their first airfoil fan blade in 1927 to improve their own facility’s ventilation, they’ve been committed to advancing air movement for healthier environments.

Today, millions breathe air moved by their fans—and that responsibility drives their relentless focus on quality. They design and build every product in-house at their Ohio facility, drawing on nearly 150 years of craftsmanship, innovation, and integrity.

Much has changed since John T. Hartzell founded the company six generations ago. Their dedication to quality never will.

Hartzell Air Movement has built its reputation on relentless innovation and commitment to engineering excellence. From its earliest days, the company focused on producing high‑performance industrial fans and air movement products, continually refining designs to address real‑world challenges. This drive to innovate is rooted in listening to customer needs, applying rigorous testing, and pushing the boundaries of materials and manufacturing techniques to ensure products deliver dependable performance in the toughest environments.

Central to the Hartzell difference is a deep understanding of airflow science and the importance of quality at every stage of production. Hartzell products are designed, built, and tested with a focus on durability, efficiency, and long service life. By combining industry knowledge with hands‑on experience and a culture of continuous improvement, Hartzell delivers solutions that help customers solve complex ventilation problems, improve system performance, and reduce maintenance costs.

Ultimately, what sets Hartzell apart is the company’s dedication to excellence — from product development and manufacturing integrity to customer support and long‑term performance. Whether for standard industrial applications or demanding custom installations, Hartzell’s approach prioritizes reliability, performance, and lasting value.

|

Hartzell Air Movement has redefined industrial ventilation with its advanced line of fiberglass fans and blowers — engineered for the most demanding environments. Drawing on decades of experience, Hartzell developed one of the industry’s first all‑fiberglass fan lines, delivering performance and longevity that surpass traditional metal products.

Fiberglass construction offers significant advantages in industrial applications:

Exceptional Corrosion Resistance — Ideal for chemical, marine, wastewater, and corrosive environments where metal would deteriorate quickly.

Lightweight Yet Strong — Fiberglass weighs 25 %–50 % less than comparable metal fans while maintaining a higher strength‑to‑weight ratio.

Stable in Extreme Conditions — It maintains dimensional stability and won’t become brittle at low temperatures.

Long Service Life with Lower Maintenance — Solid one‑piece molded components eliminate weak joints, extending life and reducing repair needs.

Cost Advantage — Fiberglass often costs less than high‑grade metals like stainless steel or Monel while delivering equal or better performance.

Impact and Water Resistant — Built to withstand tough industrial conditions and resist moisture and weathering.

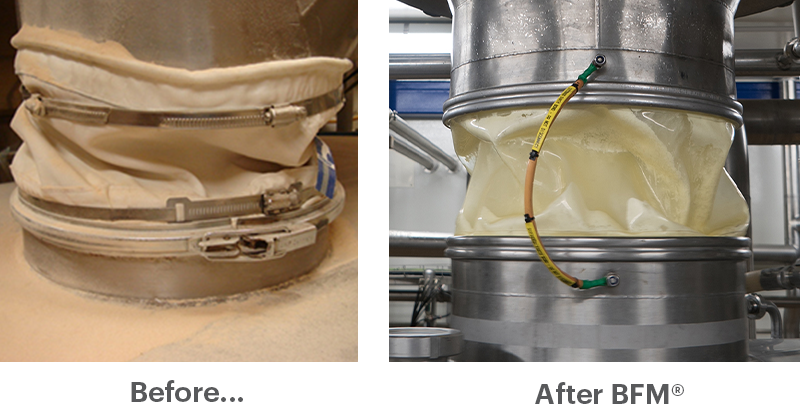

Innovative One‑Piece Wheel Design |

|

| Hartzell’s proprietary solid, one‑piece fiberglass fan wheel sets a new standard in reliability. Molded in a single operation, this design eliminates joints and potential failure points, delivering consistent performance and up to ten times the service life of traditional multi‑piece wheels. |  |

Hartzell’s fiberglass lineup covers a wide range of industrial ventilation needs, including:

Fiberglass Duct Fans – corrosion‑resistant fans for general and process duct applications.

Fiberglass Duct Axial Fans – ideal for low static, high airflow environments.

Fiberglass Centrifugal Fans & Blowers – efficient, non‑overloading designs for demanding extraction and exhaust systems.

Fiberglass Roof & Wall Ventilators – quiet, AMCA‑certified solutions for facility ventilation.

Custom Air Control Products – including specialty blowers and airflow controls tailored to specific industrial challenges.

Whether confronting corrosive fumes, high temperatures, or heavy duty continuous operation, Hartzell’s fiberglass fans deliver reliable, efficient air movement that minimizes downtime and lowers total cost of ownership.

Scrubber Fans for Industrial Scrubber Fans for Industrial |

Semiconductor Fabrication Process Semiconductor Fabrication Process |

Crypto Mining Ventilation Crypto Mining Ventilation |

Metal Surface Treatment & Finishing Metal Surface Treatment & Finishing |

Contact Craig - craig@ratetechnology.com

to learn how HARTZELL equipment and systems can benefit your operations.