BUILDING THE HIGHEST QUALITY INDUSTRIAL FANS IN NORTH AMERICA FOR SIX GENERATIONS

CSA APPROVED! - Heavy Duty - 575v Options

Capable of testing in a 12ft 50,000 CFM @ 24"wg test chamber

5 YEAR FULL WARRANTY

CSA APPROVED! - Heavy Duty - 575v Options

Capable of testing in a 12ft 50,000 CFM @ 24"wg test chamber

5 YEAR FULL WARRANTY

Fiberglass Backward Curved Centrifugal FanSeries 41Engineering Guide | Industrial Fan Guide | 41 Series Brochure | IOM Manual |

|

|

Hartzell Fiberglass Backward‑Curved Centrifugal Fans are engineered for efficient and reliable air movement in demanding industrial environments, especially where corrosion, moisture, or chemically aggressive conditions are present. The backward‑curved wheel design delivers strong performance and energy efficiency while maintaining smooth airflow and quiet operation compared to forward‑curved fans. Constructed with corrosion‑resistant fiberglass, these fans provide long service life and low maintenance, making them ideal for applications such as corrosive exhaust, industrial process ventilation, material handling, and washdown environments. Hartzell offers a range of sizes and configurations to suit different system requirements, ensuring dependable performance where durable, high‑quality centrifugal air movement is needed. Specs |

|

Fiberglass Inline

|

Fiberglass Centrifugal

|

Fiberglass

|

Fiberglass Roof

|

Fiberglass Bifurcated

|

Fiberglass Duct

|

Fiberglass Duct

|

Fiberglass Air

|

Hartzell Air Movement has redefined industrial ventilation with its advanced line of fiberglass fans and blowers — engineered for the most demanding environments. Drawing on decades of experience, Hartzell developed one of the industry’s first all‑fiberglass fan lines, delivering performance and longevity that surpass traditional metal products.

Fiberglass construction offers significant advantages in industrial applications:

Exceptional Corrosion Resistance — Ideal for chemical, marine, wastewater, and corrosive environments where metal would deteriorate quickly.

Lightweight Yet Strong — Fiberglass weighs 25 %–50 % less than comparable metal fans while maintaining a higher strength‑to‑weight ratio.

Stable in Extreme Conditions — It maintains dimensional stability and won’t become brittle at low temperatures.

Long Service Life with Lower Maintenance — Solid one‑piece molded components eliminate weak joints, extending life and reducing repair needs.

Cost Advantage — Fiberglass often costs less than high‑grade metals like stainless steel or Monel while delivering equal or better performance.

Impact and Water Resistant — Built to withstand tough industrial conditions and resist moisture and weathering.

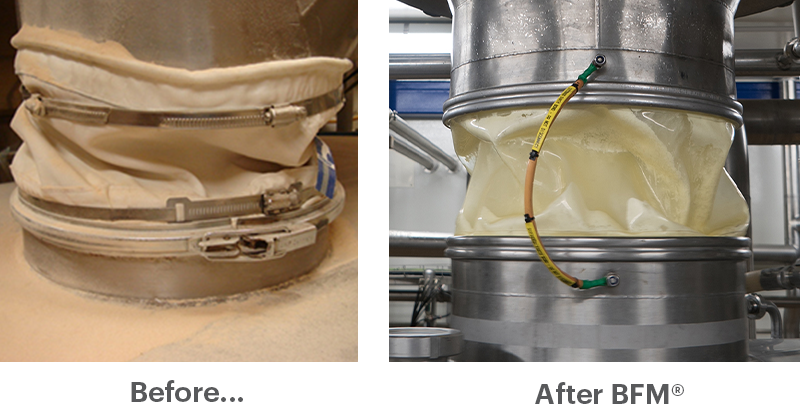

Innovative One‑Piece Wheel Design |

|

| Hartzell’s proprietary solid, one‑piece fiberglass fan wheel sets a new standard in reliability. Molded in a single operation, this design eliminates joints and potential failure points, delivering consistent performance and up to ten times the service life of traditional multi‑piece wheels. |  |

Hartzell’s fiberglass lineup covers a wide range of industrial ventilation needs, including:

Fiberglass Duct Fans – corrosion‑resistant fans for general and process duct applications.

Fiberglass Duct Axial Fans – ideal for low static, high airflow environments.

Fiberglass Centrifugal Fans & Blowers – efficient, non‑overloading designs for demanding extraction and exhaust systems.

Fiberglass Roof & Wall Ventilators – quiet, AMCA‑certified solutions for facility ventilation.

Custom Air Control Products – including specialty blowers and airflow controls tailored to specific industrial challenges.

Water & Waste Water - General Ventilation Water & Waste Water - General Ventilation |

Water & Waste Water - Process Ventilation - Axial Water & Waste Water - Process Ventilation - Axial |

Water & Waste Water - Process Ventilation - Centrifugal Water & Waste Water - Process Ventilation - Centrifugal |

Water & Waste Water - Air Control Water & Waste Water - Air Control |

Contact Craig - craig@ratetechnology.com

to learn how HARTZELL equipment and systems can benefit your operations.