BAG DUMP STATION SYSTEMS

QUOTE REQUEST | Spare Parts Inquiry

|

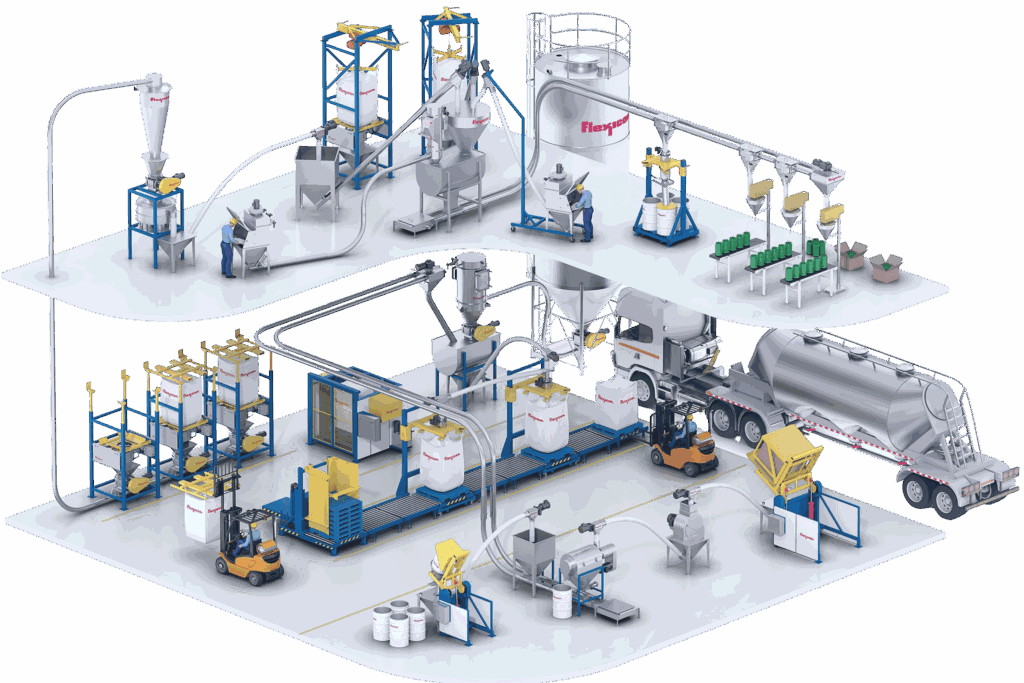

At Rate Technology Systems, we are the exclusive Canadian representatives of Flexicon®, a global leader in dry bulk material handling solutions.

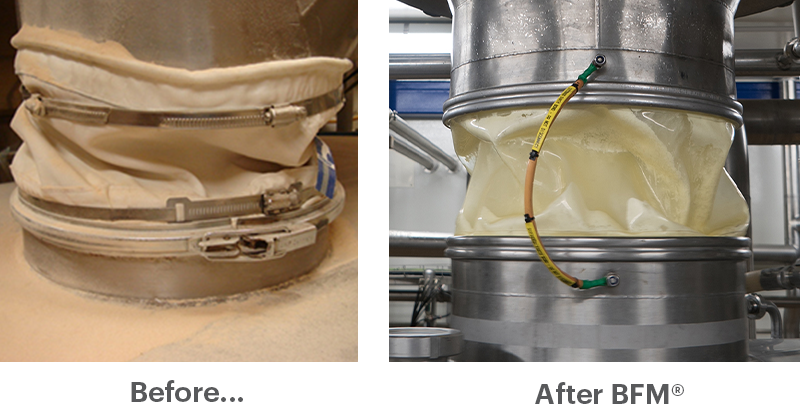

Flexicon’s Bag Dump Stations are designed to capture dust released during the manual emptying of powders and bulk solids from hand-held bags and containers.

This reduces material waste by directing collected dust back into the hopper, while also preventing plant contamination and minimizing cleanup associated with remote dust collectors.

Send us a Quote Request, and let us help you engineer the right solution for your plant.

Yes, we are offer 575v and CSA certs on motors and electrical components!

|

|

How does this system work?

Also known as sack tip or bag break stations, these units maintain a clean work environment through:

Simple Operation: Open the hood, turn on the fan, and pour materials through the hopper screen. |

Dust Control: A powerful vacuum fan draws airborne particles away from the operator into high-efficiency cartridge filters. |

Self-Cleaning Filters: A reverse-pulse system periodically blasts compressed air to remove accumulated dust from the filters, which then returns to the hopper. |

Continuous Performance: Alternating filter pulses allow for uninterrupted operation. |

Operator & Plant Safety: By capturing dust at the source, the system improves air quality and reduces material loss. |

|

Optional Features

|

|

Flexicon Bag Dump Stations can be equipped with integrated bag compactors that compress empty bags and contain dust during disposal.

Key features include:

- Seamless Integration: Bags are fed into the compactor through a chute in the dust hood.

- Dual Dust Capture: Dust from both dumping and bag disposal is routed to the same filter system.

- Safe, Dust-Free Disposal: A pneumatic cylinder compresses bags into a bin, and safety interlocks ensure operation only when all access doors are closed.

- Capacity Options: Available in models holding 50–80 or 100–150 bags, depending on material thickness.

|

|

Mobile Units - Compact, portable models can be moved between locations, supporting flexible use across the plant without needing multiple permanent installations.

|

Sanitary Design - Constructed with stainless steel and continuous welds, sanitary models meet 3-A and USDA Dairy standards. NEMA-rated enclosures make them ideal for wash-down applications.

|

|

Hopper Outlets - Customizable hopper designs are available to suit a wide range of downstream systems; such as -Adapters for flexible screw conveyor, Non-flow-through connections for pneumatic conveyors, Rotary airlock valves, and Universal flanges for direct integration with processing equipment

|

Glove Box Option - For handling hazardous or sensitive materials, the station can be equipped with a sealed glove box. Operators use built-in gloves to safely open and empty bags, providing maximum containment and minimal exposure.

|

|

BENEFITS OF BAG DUMP STATION SYSTEMS – Why These are used

|

Cleanliness & Plant Maintenance

- Simplified Cleaning: Captures dust at the source, significantly reducing airborne particles and simplifying routine cleaning tasks.

- Minimized Dust Accumulation: Prevents buildup in hard-to-reach areas, decreasing the frequency and cost of deep maintenance.

- Extended Equipment Life: Reduces dust-related wear on surrounding machinery, helping lower long-term repair and replacement costs.

|

|

Worker Safety

- Reduced Exposure to Dust: The enclosed design and vacuum system limit direct contact with fine, potentially harmful particles, helping to safeguard respiratory health.

- Ergonomic Design: The system is designed for ease of use, reducing strain on operators during manual dumping tasks.

- Dust Explosion Prevention: By capturing combustible dust particles at the source, the system reduces the risk of dangerous dust explosions in manufacturing or processing environments.

|

Where Can These Bag Dump Stations Be Used?

Flexible Screw Conveyors - Bag dump stations provide a convenient and efficient method for feeding material directly into flexible screw conveyors, supporting smooth and consistent flow.

|

Tubular Cable Conveyors - When handling delicate or friable materials, bag dump stations help load these gently into tubular cable conveyors, minimizing breakage or product degradation.

|

Pneumatic Conveying Systems - For moderate throughput needs, manual bag dump stations serve as an effective solution to introduce materials into pneumatic conveying lines, offering controlled and dust-reduced transfer.

|

Weigh Batching Systems - Bag dump stations integrate seamlessly with weigh batching setups, especially when dealing with minor or micro ingredient additions. Their precision and dust control make them a reliable choice for upstream feeding in batching operations.

|

Specialty and Hazardous Materials Handling - Pairing the station with a glove box or containment system enables safe unloading of toxic powders, allergens, potent APIs (Active Pharmaceutical Ingredients)

Filling Day Bins or Surge Hoppers - When small to medium batches need to be transferred into day bins or surge hoppers for later use, a bag dump station provides efficient, low-dust feeding, quick operator access and space-saving installation

|

Feeding Blenders and Mixers - Bag dump stations can be placed directly above ribbon blenders, paddle mixers, or cone screw mixers to feed dry powders or granular materials. This allows for controlled ingredient addition, minimized dust exposure at the mixer and improved ergonomics for operators

Pre-Screening or Pre-Sifting - Before materials enter downstream processes, a bag dump station with an integrated screen can be used to remove clumps or foreign objects, ensure consistent particle size, and protect downstream equipment from damage

Feeding Tablet Presses in Pharma/Nutraceuticals - manual ingredient addition to tablet presses or capsule machines can be done using sanitized bag dump stations with glove boxes and HEPA filtration for controlled atmosphere and safety, minimized product loss and compliance with GMP standards

Charging Dryers or Fluid Beds - Stations can also be used to introduce material into rotary dryers, flash dryers, or fluid bed dryers, especially when automated handling isn’t justified due to batch size or plant layout.

|

Featured Case Study: Hannah's Sweets

JOHNSTONE, SCOTLAND — Hannah’s Sweets, a confectionery manufacturer known for products like Jazzies and Snowies, processes up to 60 tonnes of dry ingredients weekly. To reduce manual bag handling, control dust, and maintain hygiene, the company replaced manual dumping with a Flexicon bag dump station and pneumatic conveying system.

The integrated solution handles a wide range of bulk densities and transfers material from manually dumped bags to three mixing tanks through a fully enclosed conveying system. Automated diverter valves and PLC controls ensure accurate batching, while filter receivers and dust collection maintain a clean production environment.

The system fully evacuates material during each cycle, eliminating waste and minimizing cleaning time. Since installation, Hannah’s has increased efficiency, improved sanitation, and achieved reliable, maintenance-free operation.

|

|