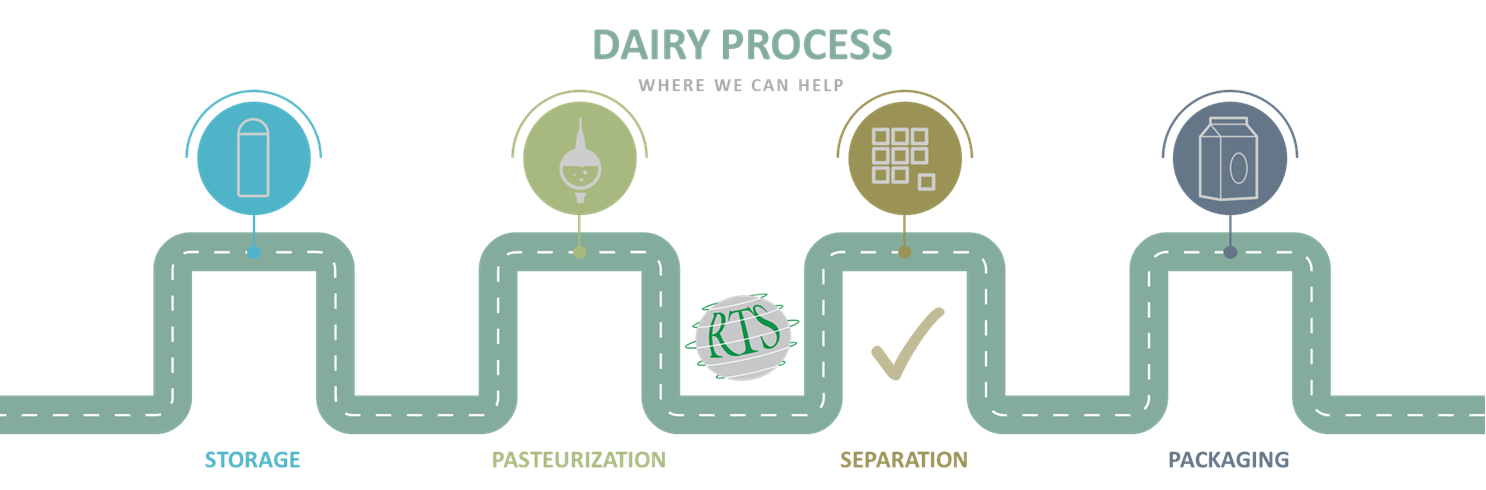

DAIRY PROCESS

Centrifugal Sifting

Dairy Plants need to sieve dairy powders.

Dairy processors rely on precision sifting equipment for their various recipe formulations. Centrifugal sifters classify the size of material by sifting and separating out material that isn’t to the required size. This screening process also removes unwanted material and de-risks the process from accepting contaminants such as plasters, insects, metals etc.

The Kemutec Kek Centrifugal Sifter is recognized as the leading industry high capacity sifter, providing unparalleled performance and benefits to users who expect the best. Fitted with a standard Cantilever Shaft, the Kek Centrifugal Sifter delivers not only the best standards of hygiene and cleanliness but also unsurpassed reliability with minimal maintenance requirements. It is available for gravity and full inline pneumatic conveying applications with output ranges from a few pounds per hour to over 100 tons per hour.