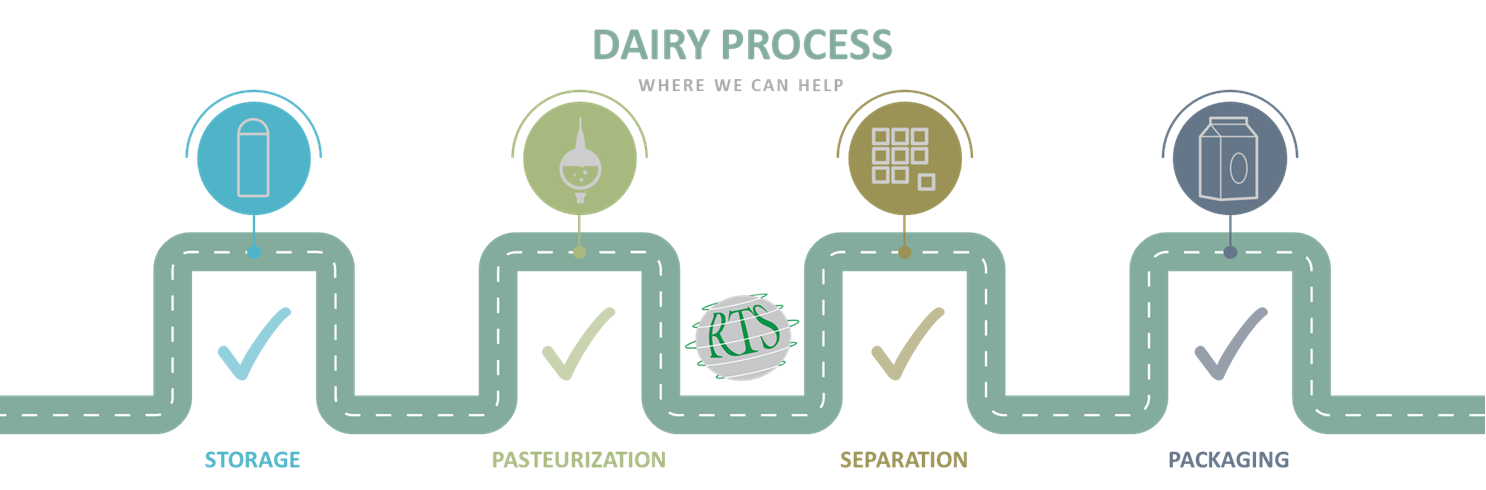

Dairy Process - Fittings

Dairy Plants are required to be of the highest sanitary standards

Dairy plants are required to be of the highest sanitary standards, with a need for continual cleaning, such as CIP (Clean in Place). They are also environments that need to be free from dust, with the risk of dust explosions.

The BFM® fitting is the perfect solution. As well as offering a component that is more abrasion-resistant than traditional connectors, the BFM® connector is easily replaced (less downtime), easily cleaned, and 100% dust-tight (eliminating plant contamination).

BFM® fittings "fit" into every stage of the dairy process from storage to packaging. Ask us how they can help you achieve the highest possible hygiene in your dairy environment.

A good fittings system will keep your production areas cleaner, saving you valuable time, money and provide a better environment for staff.

Some of the benefits of BFM® Fitting system:

| Improved hygiene: There is no more dust leakage, eliminating cross-contamination of products and reducing general housekeeping costs | |

| Health & Safety: No need for tools to remove or install the connector in difficult positions, ensuring a much safer environment for staff. | |

| Explosion resistant: The removal of dust and the antistatic properties of the BFM® Fitting products reduces the risk of secondary explosion. | |

| Reduced downtime: Fast and efficient cleaning in between product runs means downtime is significantly reduced. | |

| Easy installation: The simple snap-fit of the BFM® connector makes change-overs easy, and standard BFM® Connectors fit correctly. |

Dairy Hygiene Improved with BFM fittings

A leading New Zealand dairy plant had a major challenge with hygiene in their blending filler room.

A vibratory discharging cone was connected to the hopper via a traditional connecting sock and steel clamps. There was excessive dust leakage and product build-up in the joins – a major hygiene issue.

Since installing the BFM® fitting system, the filling room operators are ecstatic about how their work environment is now dust-free and a “pleasure to work in”.

They no longer spend hours cleaning powder off the surfaces in the filling room or have to regularly remove the messy wire-clamps and socks from the machinery to remove the product build-up between the connectors.